Definition of Smart Textiles:

According to the European Standard CEN/TR 16298-

“Smart textiles are the textile materials or textile systems that possess supplementary intrinsic and functional properties that are not normally associated with traditional textiles”.

Smart textiles allow the textile product to respond or react to the wearer or the environment in the fiber, yarn, fabric, dye or finish state; basically, they are intelligent materials. They may be passive; sensing environmental conditions without reacting, or active; sensing and reacting to environmental conditions. Smart textiles are manufactured by the application of smart materials or finishes, such as shape-memory polymers or phase-changing materials, or electronic or e-textiles.

Smart textiles or “e-textiles” incorporate electronics, lights, circuits, and other nontraditional components into fabrics and garments. For example, designers incorporate fiber-optic lights that make their clothing glow. New standards and specifications will have to be written to account for these new e-textiles. One major concern for these futuristic fibers is durability, specifically related to care. Another concern is whether the e-textile will detract from the overall appearance or hand of the garment.

Smart Textiles that are able to sense stimuli from the environment, react to them and adapt to them by the amalgamation of various functionalities in the textile structure. The stimulus can range from electrical, thermal, chemical, magnetic or other origin. Advanced materials, such as breathing, fire-resistant or ultra-strong fabrics, are according to this definition of smart textiles not considered as intelligent, no matter how high-technological they might be. The first textile material that, in retroaction, was labelled as a ‘smart textile’ was a silk thread having a shape memory.

The continual shrinkage of the textile industry in the western world has amply raised interest in intelligent / smart textiles. The amalgamation of electronic components and advanced fibers with man-made textiles extends the fields of material science and digital electronics, which results in an outcome named ‘smart textiles’ or (intelligent textiles) which falls into the category of intelligent materials that sense and respond to stimuli. Weaving functional components into conventional textiles resulted in smart textiles, which can generate and store energy, sense and respond to environmental stimuli or even communicate with users.

Recent Applications of Smart Textiles:

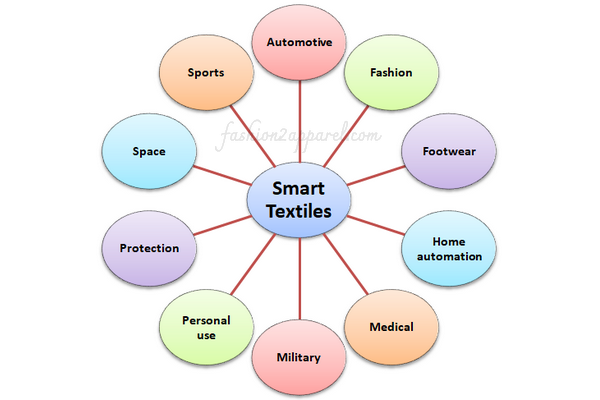

Smart and intelligent textiles are being used in various applications such as physiological monitoring (such as heart rate, respiration rate, temperature, activity and posture), sports training data acquisition, monitoring potential external hazards or hazards involved in handling of hazardous materials and tracking the position and status of soldiers in action. To evaluate these smart textiles and clothing, new instrumental analysis techniques and new test methods should be devised. The fashion and textile designers should be adequately trained in the areas of advanced fabrics and state-of-the-art technologies used in smart textiles.

Smart textile products meet all criteria of high-added value technology, allowing a transformation to a competitive high-tech industry:

- From resource-based towards knowledge-based

- From quantity to quality

- From mass-produced single-use products to manufactured-on-demand, multi-use and upgradable product services

- From ‘material and tangible’ to ‘intangible’ value-added products, processes and services.

An overview of the smart textiles application is depicted in Figure 1. Smart textiles using flexible integrated pressure sensors have many potential applications. In the medical field, these products may be used for measuring the pressure applied to the body via garments, namely hosiery or bandages for varicose veins or leg ulcers, determining the suitability of a wheelchair cushion, monitoring the wearer’s respiration, etc. In sports science, there are applications in martial arts to measure the impact or monitor the performance of muscles during exercise. Also, in home automation, objects with a textile base cause an increased interest in creating new sensor and controller products. While such smart textiles are not commercially available yet due to various challenges of textile and device integration and development of suitable functional fiber devices, their bright future has attracted considerable research interest.

There are non-woven protective garments that are used in a variety of applications such as asbestos and lead abatement, pest control and control of hazardous waste. The construction of non-wovens used in such garments provides a high barrier function against the penetration by dust, liquids or gases. The combination of three-dimensional (3D) printing production processes and nanomaterials have the potential to resolve this challenge and help to create an efficient production technology for smart textiles. This technology can be used in smart bandages, safety equipment for military use, virtual reality (VR) gloves, wearable with sensor and heat properties, medical needs, automotive and more.

The development of advanced textiles for specific applications, such as extreme sports, eventually finds its way to street fashion, where designers are allowed the creativity of experimenting with these new emerging materials.

Microfibers, for example, were initially developed for space and military applications, and are now used in sportswear, interior fabrics and fashion. Eleksen has developed fabric touchpads integrated into jackets for more accessible control of MP3 players. Another producer of electronic textiles, Textronics, developed fabrics that can warm, illuminate, conduct and sense. One of those developments was the heart rate monitoring sports bra, which had sensors that link wirelessly to a heart rate monitoring watch. To add antibacterial properties, nano-sized silver, titanium dioxide and zinc oxide are used.

Antimicrobial coatings are widely applied to socks in order to prohibit the growth of bacteria, but their uses also extend from wound dressings to home furnishings, carpets and clothing.

Another innovation for such purposes is superhydrophobic self-cleaning surfaces. It was used to resist spills, repel and release stains and resist static, leading to improvement in performance and durability of everyday apparel and interior furnishings.

Another was the Lumalive fabric from Philips, featuring flexible arrays of colored LEDs fully integrated within the fabric. These textiles are designed to enhance the observer’s mood and positively influence his or her behavior.

One of the most common applications of smart textiles is in the area of health and fitness management.

The electrical devices have applications in designing smart clothing for use in entertainment and comfort. Prototypes of fabrics with implanted MP3 players, LED and organic LED (OLED) textile displays, GPS technology and the ability to accept or dismiss phone calls have been demonstrated in the recent years. It has been shown that it is possible to place microphones and speakers into clothing, allowing the possibility of voice recognition technology or gesture-activated technologies, which allows for commands given to the clothing to perform desired tasks.

JacquardTM by Google is a technology that interacts with the smartphone, and the technology has been implemented in the Levi’s CommuterTM Trucker Jacket. This jacket allows the user to manage calls, texts, GPS and music without the need to actually pick up the smartphone (Figure 2). The jacket has LED lights and vibration options to communicate alerts, and it even has the capability to read out messages. A removable snaptag is placed on the sleeve of the jacket, which is capable of recognizing gestures to control the technology.

Smart textiles are a big concern, especially in laboratory and industrial settings. To increase workplace safety is by making the fabric material anti-static. These smart anti-static materials can be utilized to make garments with extended life and durability.

Radio frequency identification brand label technology, which is sewn onto clothing products that is resistant to hand wash and dry cleaning, discourages theft through its built-in electronic article surveillance technology to be able to identify the exact number of products that has been purchased, speeding up checkout and return procedures.

One of the least common application of smart textiles in personal health is aromatherapy. Temperature control is considered as a common consideration in smart textile production.

The smart shoe by Under Armour can be connected to the smartphone app that tracks the details such as pace, cadence, stride length and distance travelled. Medical applications of wearable smart textiles in the current world are limitless and endless. There are humidity and temperature sensor to analyze the condition of the patient. Many universities are globally working to produce clothes that allow for higher individual comfort levels and decrease the need for large amounts of heating and air conditioning and also to implement control systems by developing wireless charging systems. Fabric electrodes used to monitor ECG have been successfully implanted into wearable shirts that allow for monitoring of medical patients over a period of time. Piezoresistive fabric sensors that have been knitted into shirts have been used to collect respiratory signals.

The effectiveness of prostheses can be analyzed using sensors to record the amount and pattern of movement in rehabilitation patients. For example, the movement of a prosthetic arm can be analyzed directly or in comparison to the movement in the patient’s other arm.

Other uses of smart technology include maintaining one’s body temperature, changing color in response to environmental stimuli, creating synthetic ligaments and joints, clothes measuring the body’s immune system resistance for sick patients, clothes signalling one’s location, cooling one’s body in extreme heat, cooling products such as mats for laptops, charging electronics, self-cleaning clothes, odour-free socks, reinforcing concrete etc. Again, most of these textiles are machine washable, but some have a limited life span.

Conclusion:

Developments in smart textiles may affect many aspects of our daily lives and produce clothing that is contextually aware. Smart textiles have a large range of applications, often starting as a highly specialized application before becoming a more generally available consumer product. Textiles are also changing day by day. The hybridization of textiles and electronics brought changes in the interactive textiles. The developing field of smart textiles could show a lot of new things in all its applications. It has importance for medicine and healthcare, protective clothings and in the casual clothings and life-saving products.

As smart textile technologies became increasingly advanced in recent years, new applications have come to light. Smartphone to clothing communication is becoming increasingly popular versus other methods of reporting data from sensors within wearable smart textiles.

Implementation of wearable smart textiles in the workplace increases the overall safety through the use of anti-static and conductive properties. It has been shown to enhance the functionality of the wearer in everyday life, with designs and concepts that are being widely adopted and accepted. LED and OLED displays have been used to increase the visual appeal of clothing.

Without causing an increase in bulk, it is important to consider how the integrated electronics impact the comfort and appearance of the base clothing. With companies starting to design smart clothing for everyday use, it is not farfetched to believe that smart clothing will continue to become more advanced and seamless.

References:

- Fibres to Smart Textiles: Advances in Manufacturing, Technologies, and Applications Edited by Asis Patnaik and Sweta Patnaik

- Fibres to Fabrics by Bev Ashford

- Garment Manufacturing Technology Edited by Rajkishore Nayak and Rajiv Padhye

- Smart Textiles and Their Applications Edited by Vladan Koncar

- Wearables, Smart Textiles & Smart Apparel by Dominique Paret and Pierre Crégo

You may also like: What is Smart Textiles | List of Technologies Involved in Smart Textiles

Editor of Fashion2Apparel. She is a fashion designer and ex-lecturer in Fashion Designing. She wants to spread fashion knowledge throughout the world.