Work Aids Used in Garment Industry

Shubham Anil Jain

Aditya Birla Fashion and Retail Limited

Bangalore, India

Email: shubhamajain125@gmail.com

Introduction:

When the garment industries are concerned, the most difficult manufacturing process is sewing because it generally involves a great number of operations. The apparel production process consists of a set of workstations, at each of which a specific task is carried out in a sequence, with hundreds of employees. Sewing work aids is defined as additional working parts that are attached with the sewing machine to increase production to reduce faults and to increase quality and also help to decrease manufacturing cost. The work aids that are being used in sewing sections can be classified in a number of different ways and they vary in the aspect of their overall purpose that they emphasize some other greatly increased the speed of working in a situation where quality is already satisfactory.

Attachments to Sewing Machines:

Sewing attachment are nothing but sewing machine parts and accessories. Sewing machines attachments make sewing machines more easier and provide a variety of decorative sewing possibilities. These sewing machine attachments are mechanisms that are connected to sewing machines without cutting through or changing the original frame of the machine. When it is removed it leaves the machine in its original condition. The majority of the attachments are normally secured to the presser bar instead of the foot. A few sewing attachments ha developed ends that rest on the needle clamp. The following lists the classes and types of sewing machine attachments:

- Position attachments

- Guide attachments

- Preparation and finishing attachments

Many times it is seen that these attachments are fastened to the machines by screws or nuts and bolts. These are :

- Static – Static attachments do not move during the sewing work cycle

- Dynamic – Dynamic attachments are moved by the operator during the sewing work cycle.

- Synchronized – Synchronized attachments have a link (or links) connected directly or indirectly to one of the drive shafts of the sewing machine.

The moving link has a motion pattern that positions the fabric during the sewing element of the operation work-cycle. This positioning pattern must be synchronized with the stitching or feeding action of the machine.

Various Types of Work Aids in Garment Industry:

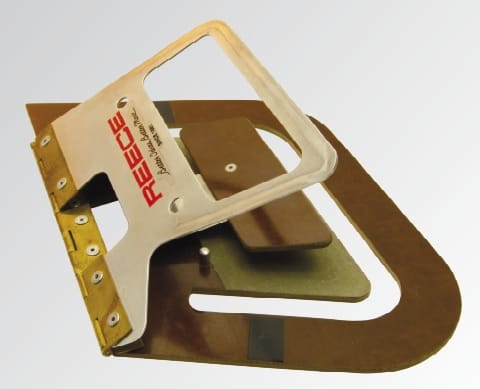

A. Folder:

This is being used in sewing for smooth production and increase the productivity as well. It is spare parts of sewing machines which are been used at various stages for different purposes. Different types and different gauges folders are available for stitching the garments. It folds one or more materials into the desired configuration for sewing. Folders are particularly designed for specific applications, which may provide for the stitching of tapes, trim fabrics, elastic and so on at the same time as the material is folded. It must need the skilled operator to sew the fabric by folding. Also the quality and productivity are other factors related to it. To increase the production and to ensure the quality of products, folder is used. There are various types of folders are available but they are divided into three main groups as given below-

- To fold the parts of garments

- To attach the parts

- To attached other materials with garments finally.

Different types of folders used in the apparel industry-

- Belt loop folder

- Binding folder

- Hemming folder

- Collar setting folder

- Cuff setting folder

- Waistband folder

- Piping folder

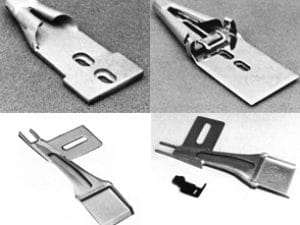

B. Stitch Jig:

The small part of garments is cut accurately by die. For precise and accurate sewing of such parts stitching jig is used. Dye cutting parts are attached with the stitching jig. It is made with two aluminum or plastic seat. Majorly used for collar and cuff operation. The main use of jig is to provide repeatability, accuracy, and interchangeably in the manufacturing of products. This device that does both functions of holding the work and guiding a tool is called a jig.

C. Slack Feeding:

Lace, braid, tape supplied in roll forms exists tension and attached in the gets in tension condition, seam pucker may be created due to shrinkage. Slack feeder is used to avoid this problem. In slack feeder, lace or braid is opened from rolls with the help of motor and roller.

D. Guide:

Guides are majorly used for correct sewing in correct position or in a determined and proper distance from edge of fabric. In sewing process, the fabric is fed to the needle over the needle plate. Fabric guides allow sewing to proceed more rapidly and precisely. Hammers and guides make it easier to feed the material correctly to the needles and to obtain a regular seam line.

E. Specialized Pressure Foot:

Specialized pressure foot used for attaching of braid or elastic. Elastication can be made using folder in the front of pressure foot. Computerized elastication m/c increase products quality and productivity.

F. Compensating Foot:

When these types of pressure feet are concerned, they have two section and these are majorly spring connected. These are use for sewing plies of different thickness. These type of foot also used for sewing very narrow border. Compensating pressure foot is used in patch pocket, collar closing seam etc.

G. Light:

Nowadays, a flexible LED lamp light is used for industrial sewing machine. It is useful when sewing or even for any other purpose where you need additional light. The magnetic holder attaches to any metal. Single lamp holder is easy to use as it can be rotated. Universal hose, switch socket and with strong magnet. Can be directly attached to the equipment machine, easy installation and use.

H. Latch Back Devices:

In over edge sewing machine the thread cutting ends can be secured with the air flow latch back. In this method one end can be lace back.

Conclusion:

Work aids is considered as an important and one of the essential part of any garment industry. Working Aid is one of the most effective sewing tools. When the domestic production of garments are considered, 50% of the time is wasted for the handling of fabric and only 50% used for sewing. To reduce this wastage in industrial production of garments work aids required. These work aids are not only used to reduce the handling time but also used to improve the quality of the garment in industry. The extent of process control in maintaining the processing parameters at desired level can be reduced thereby maintaining quality & increasing productivity.

References:

- Kiron. Mazharul Islam, Working Aids in Sewing Machine and Garment Production, https://textilelearner.net/working-aids-in-sewing-machine/

- Raihan.S Effect of Sewing Work Aid in Garments Production. International Journal of Textile Science. 2016; 5(3): 49-59.

- Manufacturing Facility for Apparel, Textiles Government of Gujarat, [08/02/2017] Available from: http://textilefashionstudy.com/types-of-fabric-used-in-apparel-manufacturing.

- Harold Carr and Barbara Latham, 2nd Edition, 1994. “Types of work aid “, The Technology of Clothing Manufacture”, Blackwell Science.

- Effect of Sewing Work Aid in Garments Production, Sojib Raihan, Department of Textile Engineering, Southeast University, Dhaka, Bangladesh

- Work Aids of Garments Sewing Machines | Different Types of Folders Used in Garments Sewing Machine

You may also like:

- Sewing Machine Parts and Functions with Pictures

- Different Types of Embroidery Machines and Their Functions

Editor of Fashion2Apparel. She is a fashion designer and ex-lecturer in Fashion Designing. She wants to spread fashion knowledge throughout the world.