Sewing Thread:

Sewing threads are special kinds of multi-yarns that are engineered and designed to pass through a sewing machine rapidly for joining or making garments. Sewing threads must be durable enough to withstand the abrasion, stretch and needle heat that occurs while sewing, garment finishing, stretching and recovery during wear. The basic function of a thread is to deliver aesthetics and performance in stitches and seams. Even a small sewing thread failure leads to losses on investments in material, equipment, apparel engineering and labor. Sewing performance and seam quality could be influenced by sewing threads parameters, selection of proper thread and utilization of thread. Sewing thread is a unique type of yarn, engineered and constructed to move through a needle and other components of a sewing machine swiftly. The fundamental task of a sewing thread is to produce aesthetic and performance in stitches and seams.

Classification of Sewing Threads:

Sewing threads can be classified in different ways–

- Sewing threads can be classified based on substrate or material, for example polyester, cotton, lyocell, meta-aramid, para-aramid, nylon, polypropylene and PTFE;

- Sewing threads can be classified based on construction, for example air-entangled, braided, poly-cotton core spun, poly-poly core spun, monofilament, spun, spun-stretch broken, textured, twisted multifilament and monochord; and

- Sewing threads can be classified based on finish, for example bonding, non-wick, anti-fungal, fire retardant, water repellent and anti-static finishes.

Hundred percent polyester thread is used for sewing fabrics of all different fiber content; this is primarily due to the fact that cotton has less elongation property and is not suitable for high-speed sewing. In addition, the incompatibility of post-washing shrinkage between cotton sewing threads and cotton fabric may lead to shrinkage pucker. Hundred percent cotton spun thread is used only for garment dyeing. Poly-poly core spun thread is 40-50% stronger, has higher abrasion resistance, has a smaller diameter with the same breaking strength, shows optimized elongation behavior, has less shrinkage, exhibits fewer knots and thick and thin parts in between, runs with minimal tension, is suitable for high-speed and multi-directional sewing machines and has less fiber falling on the machine, so less maintenance compared to 100% cotton thread.

Properties of Sewing Thread:

Requirements of good quality sewing threads are given below:

- Good tensile strength to grip the seam firmly during wash and wear. The thread strength should be higher than the fabric so it will not rupture during wear.

- Higher initial modulus of thread guarantees the least thread deformation during shock loading in sewing. The sewing threads should be moderately stiff to form the loops for stitch formation.

- Smooth surface and negligible faults in thread provides minimum friction between the needle and sewing threads while sewing at high speed. It should be adequately lubricated to improve the abrasion resistance and its sewability.

- Uniform thickness provides even sewing threads, which ensures smooth passage of thread through the needle and the fabric.

- Good elasticity facilitates the thread to recover its original length instantly after the tension has been released. The elastic property of thread influences the strength and quality of a stitched seam.

- Good color fastness of thread creates resistance to the various chemical agents the thread is exposed to during garment manufacturing and washing. The thread should be dyed evenly and uniformly.

- Lower shrinkage characteristics of the thread comparable to the fabric shrinkage to avoid shrinkage puckering on garments. Cotton threads usually undergo washing shrinkage puckering while synthetic threads suffer from the thermal shrinkage during ironing.

- Better chemical resistance is an enviable characteristic for sewing threads in garments that could undergo washing, bleaching or dry cleaning during wear.

- Higher abrasion resistance provides a good sewing performance and makes the thread more durable.

- Good color fastness could maintain the original color of sewing threads without any fading while it is exposed to washing and sunlight.

- Minimum metamerism could be attained by the measurement of thread color with color matching cabinets. Metamerism is an intrinsic characteristic of a thread when the same thread color appears to be dissimilar under diverse lighting conditions.

Factors Influencing the Aesthetic Characteristics of Sewing Threads:

Fineness, color and luster must be taken into account when selecting a sewing thread for decorative purposes. Other considerations influencing the aesthetics of sewing thread are

- Hue and shade

- Color fastness

- Stitch selection

- Even stitch formation

Factors Affecting Performance of Sewing Thread:

Sewing threads used in garments should be durable to withstand the abrasion during wear and needle heat that occurs while sewing, finishing of garments and during wear. Sewing threads performance could be assessed from its

- Seam strength

- Abrasion resistance

- Elasticity

- Chemical resistance

- Flammability

- Color fastness

Basic Requirements of Sewing Thread:

Sewability:

Sewability is a capability of sewing threads to produce a seam with a minimum number of sewing threads breakages and the slightest damage to the thread and the fabric during the stitching process.

The parameters that determine sewability of thread are:

- No thread breakages in high-speed sewing

- Consistent stitch formation

- No skipped stitches

- Evenness of yarn

- Higher abrasion resistance

- Adequate smoothness of thread surface

Thread performance in seam:

It is the capacity of a thread to produce the desired functional serviceability in a desired seam.

…………………………………………………….Seam Tensile Strength x 100

Seam Efficiency Index (SEI) = ——————————————————–

……………………………………………………….Fabric Tensile Strength

Proper choice of thread needs consideration of its performance during sewing as well as under conditions of wear and cleaning. As like other textile materials, sewing threads are composed of a fiber type, yarn construction and a finish, which all have an influence on appearance and the performance of the thread. Extensive ranges of thread sizes are available; the selection of the proper size depends on the fabric to be sewn as well as the needle size used in the machine.

Twist of the sewing threads:

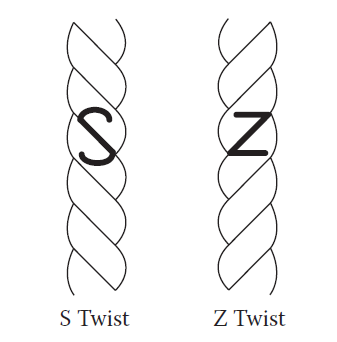

Sewing threads are mainly produced in three-ply and occasionally two- or four-ply. Three S twisted single yarns are Z twisted to form a three-ply sewing thread. The finishing twist is in the Z direction to reach equilibrium and resist further tightening of twist. However, if the sewing thread is having an S twist as a finishing twist, the thread will get untwisted by the sewing action and may fray and break. As the lockstitch machine is the most severe in its handling of thread, the majority of sewing threads intended for use in a sewing machine are constructed with a finishing Z twist.

Twist of the sewing threads denotes the turns per unit length needed to keep the fibers or yarns together to provide the required strength as well as flexibility to the yarn/ thread. Higher twist in thread leads to twist liveliness which could result in snarling, knots and loops which restricts the formation of a stitch. Sewing thread direction could be either ‘S’ for left twist or ‘Z’ for right twist (Figure-2). The majority of single needle lock stitch machines and other sewing machines are intended for ‘Z’ twist threads as ‘S’ twist in sewing threads tends to untwist during the formation of a stitch.

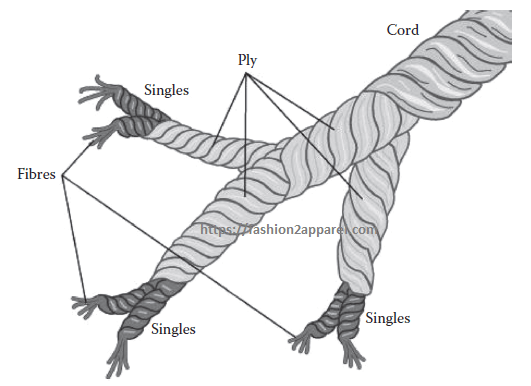

Normally single yarns of ‘Z’ twist are combined together and are twisted in an ‘S’ direction for sewing threads. Since the rotation of the bobbin hook could untwist some portion if it is twisted in a ‘Z’ direction during its normal rotational direction, the doubling twist is normally kept in the ‘S’ direction. For producing a sewing thread, single yarns are combined and twisted together to produce a ply thread. Further, the resultant threads are again combined and twisted together for producing a corded thread as shown in Figure-3.

Sewing thread size:

Sewing thread size is the most significant factor in accomplishing the functional and aesthetic requirements of the finished garment. Sewing threads sizes could be expressed in direct or indirect numbering systems. Normally, metric count (Nm) is used to express synthetic, spun and core spun thread size while English count (Ne) is used to express the size of cotton thread. Filament sewing threads are generally expressed in denier or decitex.

In direct systems: Resultant thread size = Single yarn count/Number of plies

In indirect systems: Resultant thread size = Single yarn count × Number of plies

Ticket Numbering:

Ticket numbering is a commercial sewing thread numbering method for expressing the sewing threads size. These are simply the manufacturer’s reference values for the size of a given sewing thread. The metric system, English system and Denier systems are generally used to arrive at the ticket number of the finished sewing threads. A value of a ticket number in one type of sewing thread will not be the same as in another. For example, Ticket 40 cotton is not the same as Ticket 40 core spun thread. Generally, the higher the ticket number, the finer the thread and vice versa.

For cotton sewing threads (IS: 1720-1978):

Normally, the ticket number is related to 3-ply construction as a base; the number indicates the single yarn count (Ne). For example, Ticket number 60 represents 3/60s or 2/2/80s or 3/2/120s of which resultant count is 20s.

……………………………………………Single yarn English count (Ne) x 3

Cotton ticket number = —————————————————————

………………………………………………………..Number of ply

For synthetic sewing threads (IS: 9543-1980):

………………………………………….Single yarn metric count (Nm)

Metric ticket number = ——————————————————-

…………………………………………………..Number of ply

You may also like: Different Types of Embroidery Machines and Their Functions

Editor of Fashion2Apparel. She is a fashion designer and ex-lecturer in Fashion Designing. She wants to spread fashion knowledge throughout the world.