Feed Mechanism of Sewing Machine:

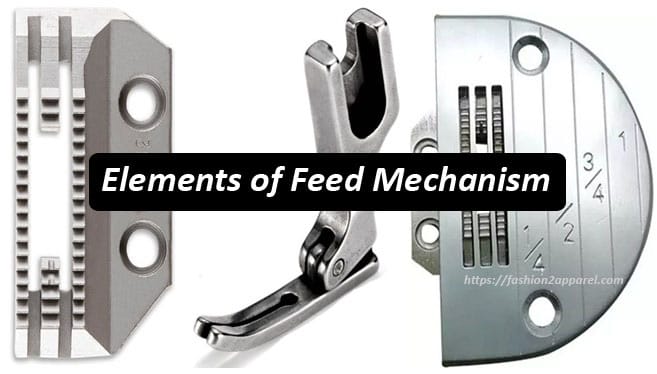

The sewing machine feeding systems are used for handling fabrics in a controlled manner during stitching for continuous sewing. For producing an accurate straight line of stitches, the fabric must be moved through the stitch forming area of the machine precisely and accurately. The feeding mechanism comprises three elements, namely, presser foot, throat plate and feed dog. Each of these components has many variations in shapes and sizes. Application of these appropriate elements of feeding mechanism depends on the type of sewing machine, number of needles used, types of attachments used and types of operations.

Elements of feed mechanism is one of the controls available on sewing machine. It controls the length of the stitching. The feed mechanism of sewing machine controls the amount of fabric fed by feed dog during every sewing cycle of needle. The three sewing machine parts, which together constitute the drop feed mechanism are presser foot, throat plate and feed dog. They are also known as the basic elements of feed mechanism.

Elements of Sewing Machine Feed Mechanism:

Presser foot:

The presser foot can be raised and lowered with a small lever at the back of, or beside, the needle. It is the upper component of the feeding system that grips the fabric during the feeding action and stitch formation. The presser foot, which is fitted on to the presser bar, controls the quantity of pressure applied on the fabric panel as it is fed through the sewing machine. The extent of pressure to be exerted on the fabric can be varied based on the stitching speed and fabric construction and weight. Higher sewing speeds may require more pressure to control the movement of the fabric.

When the presser foot is up, it permits the movement of the fabric freely. When the presser foot is down, it presses the cloth against a base plate.

A basic presser foot could be assembled as a single unit or hinged to facilitate movement over bulky seams. The universal type is the flat presser foot, which comprises a shank that attaches to the presser bar and the shoe that rests on the fabric surface is shown in Figure 1.

Variations in the basic presser foot take place in the shoe component, which involves the sole, heel and toe. The sole is the flat area that has direct contact with the fabric, which could be made smooth, toothed and so on. The toe is the front portion of the shoe that is accountable for guiding, holding and positioning the unsewn fabric. The heel is the back part of the shoe that is mainly responsible for holding fabric and retaining its established position for the feeding and stitching action to take place.

Some of the modifications of presser foot are offset soles for stitching along raised edges of fabric, short toes for sewing curves, long toes for long straight seams, channelled soles for fitting over bulky lapped seams, solid narrow feet for sewing close to raised edges and so on.

Feed dog:

The main element in a feeding system is the feed dog, which transports the fabric by a preset length between succeeding stitches. A set of feed dogs, which look like short, thin metal bars, are crosscut with grooves, move to and fro in the throat plate slot which is marginally bigger than the feed dog as shown in Figure 7.2. The typical four motions performed by the feed dogs such as forward, then downward, then backward and then upward aid to transport the fabric for continuous stitching. The feed dogs are in contact with the fabric panels on the forward movement and are pulled down below the main plate on the backward movement by the sewing machine’s mechanism.

During the stitching process, after every successive stitch, predetermined amount of fabric is moved by feed dog. In normal single needle lockstitch machine, typically a set of feed dog with two or three rows will be present. Once the cycle is completed, the feed dog drops below the throat plate. In this time, this plate supports the fabric from falling away and so that it loses contact with the feed dog and is not carried back with it.

If the shape of the feed dog is sharp at the top end, it may damage the material and cause thread breakage or chain off thread break. To avoid this, the feed dog may be grinded with grindstone on the surface slightly.

Throat plate:

They are removable metal plates secured to an adapter plate directly under the needle. Throat plates keep the fabric panel as the needle penetrates to form the stitch. Throat plates have openings for needles to pass through and for the feed dog to come up. The selection of the throat plate with respect to its shape and size is based on the type of sewing machine and its specific function in the stitch-forming process. Throat plates are interchangeable and must be compatible with other stitch forming and fabric-carrying parts in order for stitches to be formed properly.

The main function of the throat plate is to provide a smooth, flat surface over which the fabric passes as successive stitches are formed. It has one or more slots in it which matches the sections of the feed dog. Throat plates must be changed at regular intervals after checking for wear and tear. Besides, throat plates must be changed in accordance with the needle size even if there are no signs of wear and tear.

Conclusion:

The feed mechanism is a vital component of a sewing machine that ensures the fabric moves consistently and precisely for uniform stitching. Primary elements of sewing machine feed mechanism like the presser foot, feed dogs, throat plate, and adjustable controls, the mechanism allows for versatile sewing operations, including various stitch lengths, directions, and fabric types. Understanding these elements helps in maintaining the machine’s performance and achieving high-quality sewing results.

References:

[1] Karthik, T., Ganesan, P., & Gopalakrishnan, D. (2016). Apparel Manufacturing Technology. In CRC Press eBooks. https://doi.org/10.1201/9781315367507

[2] Nayak, R., & Padhye, R. (2015). Garment Manufacturing Technology. In Elsevier eBooks. https://doi.org/10.1016/c2013-0-16494-x

[3] Sinclair, R. (2015). Textiles and fashion : materials, design and technology. In Woodhead Publishing eBooks. http://ci.nii.ac.jp/ncid/BB18427651

[4] Rathinamoorthy, R., & Surjit, R. (2015). Apparel Machinery and Equipments. In WPI Publishing eBooks. https://doi.org/10.1201/b18903

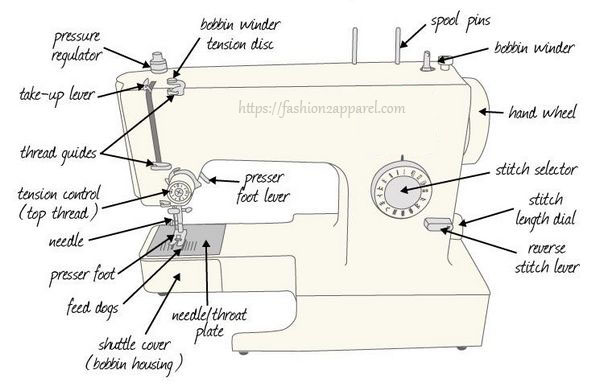

You may also like: Sewing Machine Parts and Functions with Pictures

Editor of Fashion2Apparel. She is a fashion designer and ex-lecturer in Fashion Designing. She wants to spread fashion knowledge throughout the world.