Finishing Department in Garment Industry:

In the apparel industry finishing department is the final stage for garment manufacturing. After completing the cutting and sewing performance, sewing section send their complete garment to the next section it’s called finishing section. For getting the finishing touch, defects free and quality passed garments are come from the sewing department. Main finishing activities like as thread remove, ironing or pressing, measurements check, quality inspection, folding, label attaching, hang tag and barcode attaching, poly packing, and packaging should be implemented here. Every instruction of buyer and specifications has to be followed in this finishing department.

To do these finishing activities garment industry used different types of finishing machines, tools and equipment. These types of garment finishing equipment are also used for attaching finishing accessories in apparel industry.

Essential Garment Finishing Machines, Tools and Equipment in Apparel Industry:

In apparel industry, finishing is the final stage where garments are enhanced to improve their appearance, feel, and performance. It includes processes such as pressing, folding, packaging, and applying functional finishes (like wrinkle resistance or water repellent).

Before arrange a final inspection, finishing inspector use some essential finishing machines, tools and equipment for complete finishing treatment and produce zero defects of garments.

Here’s a categorized list of finishing machines, tools, and equipment used in this stage:

1. Pressing and Ironing Equipment

These tools help remove wrinkles, shape garments, and improve presentation.

- Bodies dummy

- Boiler

- Compressor

- Iron cap

- Iron plate

- Steam Iron (dry or steam)

- Steam Press

- Vacuum Ironing Table

- Buck Press

- Steam Boiler (for centralized steam supply)

- Form Finisher / Steam Dummy (for jackets, coats, shirts)

- Collar/Cuff Press

- Trouser Topper

- Leg Seam Pressing Machine

- Sleeve Pressing Machine

2. Folding and Packing Machines

For neat folding and packaging of finished garments.

- Automatic Folding Machine

- Shirt Folding Board / Template

- Stand-up shirt folding table

- Poly Bag Inserting Machine

- Tagging / Labeling Machine

- Carton Sealing Machine

- Barcode Printer & Scanner

- Strapping Machine

- Conveyor Belt System

3. Stain and Spot Removal Equipment

Used for removing oil, ink, or other stains from garments before packing.

- Spotting Gun

- Spotting Table (Vacuum Table with Lighting)

- Stain Removing Chemicals

- Steam Gun

- Spray gun (For spot remove)

- Compressed Air Gun

4. Quality Control and Inspection Tools

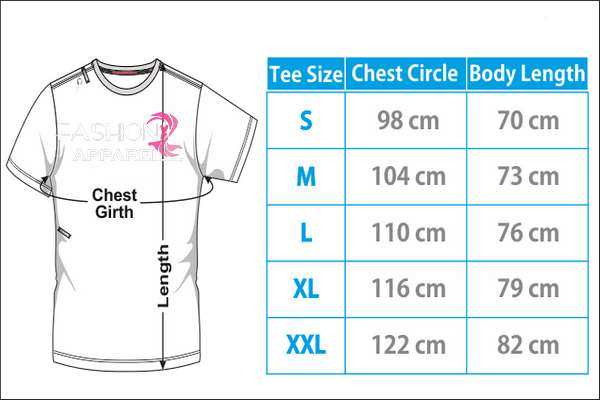

Ensure garments meet required standards before dispatch.

- Final inspection table

- Measuring Tape / Scale

- Needle Detector Machine (especially in children’s wear)

- Light Box (Color Matching Cabinet)

- Fabric Inspection Machine

- Thread Sucking Machine

- Magnifying Glass

- Stitch Density Checker

- Garment Checking Stand

5. Finishing Treatment Machines

Used for applying various functional or aesthetic finishes.

- Hydro Extractor (for wet finishes)

- Garment Washing Machine

- Tumble Dryer

- Ozone Finishing Machine

- Spray Booth (for resin, fragrance, etc.)

- Curing Oven (for heat setting finishes)

- Laser Finishing Machine (for denim wear effects)

- Heat Press Machine (for transfer prints or foil)

- Heat Sealing Machine

- Fusing Machine

- Embroidery Backing Trimmer

6. Miscellaneous Tools and Equipment

- Lint Roller / Brush

- Thread Trimmer / Snipper

- Garment Hanger

- Packing Table

- Hot Air Gun

- Tag gun

- Scissors

- Electric Scissors (for trimming)

- Label Cutter and Dispenser

- Weight scale

To improve garment appearance, feel, and performance finishing inspector used these garment finishing equipment. These tools and machines play crucial roles in achieving the desired quality and zero defects of garments in the finishing section of production.

Editor of Fashion2Apparel. She is a fashion designer and ex-lecturer in Fashion Designing. She wants to spread fashion knowledge throughout the world.