Quality Inspection:

In the apparel industry different types of inspections are happened for improving garments quality. It helps to prevent defects in manufacturing process. Inspection is one of the main tools of quality assurance. During garment production to ensure quality there are apply 4 types of inspection process.

Types of quality inspection process:

- Inline quality inspection

- Table inspection

- Pre-final inspection

- Final or Pre shipment inspection

Inline Quality Inspection in Garment Industry:

Inline Quality Inspection means inspecting goods at the time of production, so that any defect occurring at this time may be located at the earliest stage or as is called at needle point and may be easily repaired. Inline inspection is a crucial step to ensure that garments meet the required quality standards at various stages of production in garment industry. This process is done instead of checking at the end of the process. Thus repair becomes easy and cost remains lower. Thus garments defects rate remains at minimal.

Required Tools and Equipments for In-line Quality Inspection:

An in-line inspector is a person who conducts quality inspection while the work is in process or in progress. He identifies the defects at the needle points. The inspector must be a trained person and he must be equipped with the following tools, equipment’s and environment also.

Basic tools and equipment’s for inline quality inspection in the garment industry are listed in below:

- A medium size table (Of greenish grey color) lit with tube lights having light quantity to the tune of 1000 lux.

- Measurement tape.

- Another measuring tape that fixed on the table; the tape should be metallic origin.

- Good quality scissor.

- Need arrow sticker for display the location of defects, etc.

Key Guidelines to In-line Quality Inspection:

In order to successfully conduct quality inspection of garments some guidelines must be needed. For inspection purpose the inspector should pursue the following guidelines:

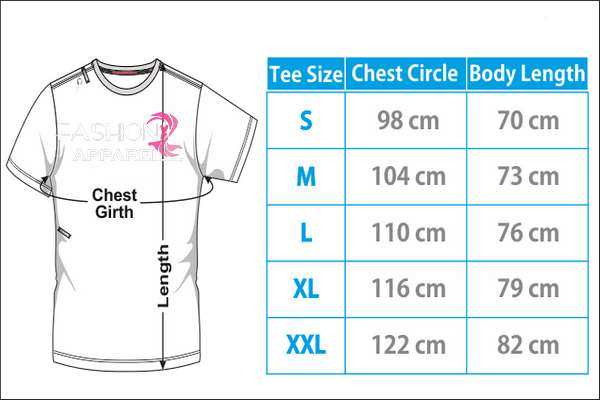

- Quality Inspector must have a worksheet along with size-spec and special buyer instruction, if there is any.

- For each style there should be an approved sample in close proximity to the inspector.

First pre-production and production samples must be closely monitored and inspected to check the following:

- Check size-spec rigorously.

- Check sewing defects and non-sewing defects.

- Check if there is any oil marks, stain marks or shading.

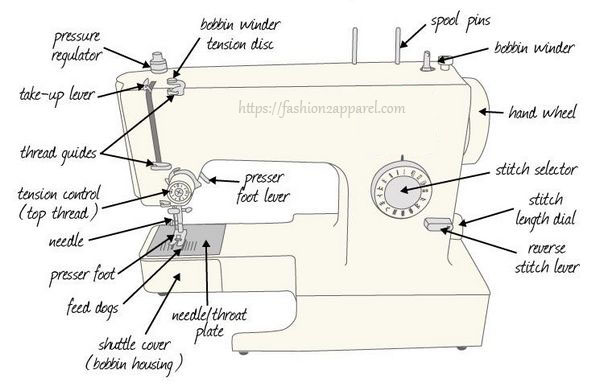

- Check if there are defects due to sewing machine, needle, thread, or feed mechanism, etc.

- Check if right color and type of thread, button, zipper, lining, shell, label, logo, etc. have been used.

- Check if buyer’s special instruments have been followed or not.

- Check location of major defects and identify why they originated.

- Ensure that machines, tables, and operators hands are clean.

- Ensure that right type of needle, feed-mechanisms, etc. are in use.

- Always follow worksheet, buyer’s instructions, size-spec, and assortment.

Conclusion:

Inline inspection in garment industry helps manufacturers to identify and rectify defects early in the manufacturing process, reducing the number of defects in the final product and ensuring that the garments meet the desired quality standards. By doing so, it minimizes the chances of large-scale rejections or rework, thus saving time and resources for both garment manufacturers and buyers.

Editor of Fashion2Apparel. She is a fashion designer and ex-lecturer in Fashion Designing. She wants to spread fashion knowledge throughout the world.