What is Flax Fiber?

Flax is the most strongest among the natural cellulosic fibers. It is the first plant stem (bast) fiber used by man for making textiles, particularly in the West. Flax fiber is extracted from the skin of the stem of the flax plant. In its inner bark, there grows long, thickwalled cells of which flax fiber strands are composed. Flax is manufactured into linen yarn for thread or woven fabrics. So it is also called linen. It is also one of the oldest fibers, which was used more than 30,000 years before. Linen cloth made from flax was used to wrap the mummies in the early Egyptian tombs.

Flax is used in connection with the plant and products that are made directly from it or that are closely associated with it. For example, flax fields, flax cultivation and production, line flax (long fiber flax), flax tow (short fiber flax), flax spinning and flax yarns, and also certain types of flax fabrics, especially those of a heavier industrial kind.

Properties of Flax Fiber:

Flax is soft, lustrous, and flexible; bundles of fiber have the appearance of blonde hair. It is used to make most of the expensive cloth which is most comfort to wear. Flax fiber absorbs humidity well and is a very breathable fiber.

Physical properties of flax fiber:

1. Tenacity: Flax is a very strong fiber because it’s very crystalline polymer system permits its extremely long polymers to form more hydrogen bonds than cotton polymers. Tenacity varies from 6.5 to 8 gm/denier.

2. Length: The average length of fiber various from 18-30 inch.

3. Color: Brownish, light, ivory, grey.

4. Elongation at break: The elongation at break is approximately 1.8% (dry) and 2.2% (Wet).

5. Specific Gravity: Specific gravity is 1.54.

6. Effect of Heat: Linen has an excellent resistance to degradation by heat. It is good conductor of heat. So linen sheet are so cold in summer season.

7. Hygroscopic nature: Flax is very absorbent.

8. Effect of moisture: Standard moisture regain is 10 to 12%.

9. Absorbency: Absorbency is good. It absorbs moisture and dries more quickly. It is excellent for manufacturing towels and handkerchiefs.

10. Dimensional stability: Good but easily tend to crease.

11. Resiliency: Very poor.

12. Comfortable: Linen is a comfortable fabric.

13. Good Abrasion Resistant: As the linen fiber is good in strength, it also has good abrasion resistance.

14. Lusture: It is brighter than cotton fiber and it is slightly silky.

Thermal properties of flax fiber:

1. Flax has the best heat resistance and conductivity of all the commonly used textile fibers.

2. Excessive application of heat energy causes the flax fiber to scouch, char and burn. This is an indication that flax is not thermoplastic which may be attributed to the extremely long fiber polymers and the countless hydrogen bonds they form.

Chemical properties of flax fiber:

1. Effect Acids: Flax will withstand in weak acids but is attacked by hot dilute acids or cold concentrated acids.

2. Effect of organic solvents: Resistant of common solvents (Acetone, ether, methyl, alcohol, Chloroform Etc.)

3. Bleaching Actions: Cool chlorine and hypo-chlorine bleaching agent does not affect the linen fiber properties.

4. Effect of insects: Flax is not attacked by moth, grubs or other insects.

5. Effect of Micro Organism: Linen fiber is attacked by fungi and bacteria.

6. Effects of Alkalis: Linen has an excellent resistance to alkalis. It does not affected by the strong alkalis.

7. Dye ability: It has no good affinity to dyes. Direct and vat dyes are suitable for flax.

Uses of Flax Fiber:

Flax is two to three times stronger than cotton fiber, but less elastic. The best grades are used to make linen fabrics such as damasks, sheeting and lace. Coarser grades are used for the manufacturing of rope and twine, and historically for canvas and webbing equipment. Flax is also used as a raw material in the high-quality paper industry for the use of printed banknotes and rolling paper for tea bags and cigarette paper manufacture. It is also hypo-allergenic and so an excellent choice of fiber for those with allergies.

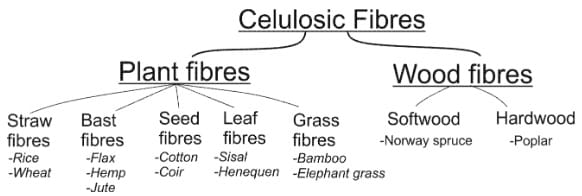

Flax has an important application as composite material. It is a cellulosic fibers, like wood and plant fibers; it has the potential for use as load-bearing constituents in composite materials due to their attractive properties such as high stiffness-to-weight ratio that makes cellulosic fiber composites ideal for many structural applications.

Flax, in all its forms, is used in food production, personal care products, animal feeds, fiber and a number of other industrial uses.

Common uses of flax:

- Clothing apparel

- Sewing thread

- Surgical thread

- Sanitary napkins

- Decorative fabrics

- Table wear

- Bed linen

- Wall coverings

- Suiting

- Kitchen towels

- Dish towels

- High quality papers

- Handkerchief linen

- Shirting

- Upholstery

- Draperies

- Curtains

- Artist’s canvases

- Luggage fabrics

- Paneling

- It is used in Insulation purposes

- Filtration

- Fabrics for light aviation use

- Used in automotive industry

- Reinforce plastics and composite materials.

- Used in geotextiles (ground-cover materials).

- Flax could conceivably be mixed with excess grass seed straw or softwood fiber in composite boards

Editor of Fashion2Apparel. She is a fashion designer and ex-lecturer in Fashion Designing. She wants to spread fashion knowledge throughout the world.