Garment manufacturing is very lengthy and complex process. There are thousands of technical terms used in garment industry. Whole garment production process is not easy to keep in memory. If garment technologist can learn some important garment industry terminology then it will be easy to operate his duty. Besides, to know garment manufacturing terms and definition is very important job seekers. Because those apparel production terms and process are frequently asked in job interviews. In this article I have given most frequently used terms and definition in garment industry. All terminology are given in alphabetically.

List of Technical Terms Used in Garment Industry:

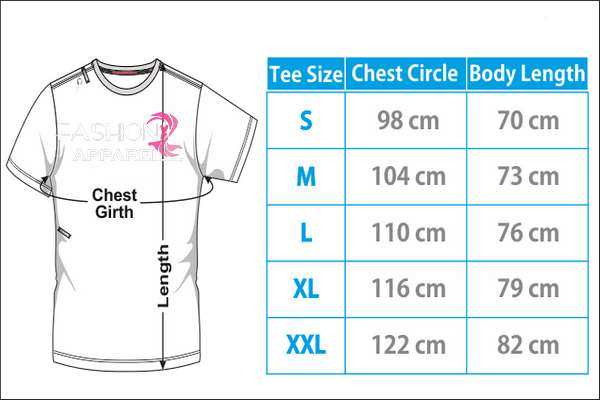

Allowance: The addition as extra to the exact measurement of the body with which a garments is made out is called allowance.

Appliqué: A cut out design or shape attached to the face of a fabric for ornamentation of garments is called appliqué.

Arm Scye: The arm hole of garments is called arm scye.

Automatic cutting device: A computer-controlled knife, laser, water-jet, plasma or ultrasound used to cut textiles and other materials.

Back Stitch: It is one kind of hand stitch which can be done by machine.

Back-tacking: Back-tacking is sewing in reverse and forward over the same stitches to secure a line of sewing; this can be done at the beginning and the end of a seam to prevent the stitching from unravelling.

Bar Tack: Re-stitching over a very short length and increase the area of a high load bearing strength is called bar tack. For example: Belt loops and comers of pocket are comers of pocket are bar tack.

Base (Core spun thread): It is a one kind of special type of sewing thread in which center filament is remained and in outer side staple fiber is remained. These yarns are normally produced to give strength and elasticity to the fabric.

Basic Block: It is an individual component of garments without any design or style.

Basting: The process of non permanent sewing for placing perfect place just before final sewing is called basting. It can be done by manually or by m/c.

Blind Stitch: The special type of stitch which is not visible at the surface at the face side but the sewing tread is visible of back side is called blind stitch.

Blind Stitching: Special kind of stitch that does not surface at the face side but the sewing thread is visible of backside. This stitch does not penetrates and perforate fully.

Bodice: The specific part of women garments which are expanded from neck to waist is called bodice.

Bound/binding: A strip of fabric cut on the bias (cut at 45° to the straight grain of the fabric) which is used to finish off /neaten the raw edge on a garment such as an armhole.

C and F: If the price of goods is mentioned in invoice including transport cost is called C and F.

C.F Line: The front of a shirt line from the collar to downwards in which buttons are attached is called C.F line.

C.I.F: II the price of goods is mentioned in invoice with including transports cost and insurance cost.

Category: The number which indicates what type of fabric used for making the garments and it also indicates what type garments to be made is called category.

Cheese: A cylindrical package of yarn on which a single thread is laid at an appreciable helix angle is called cheese.

Classification of Seam:

- Seam class I (Super Imposed Seam)

- Seam class II (Lapped Seam)

- Seam class – III (Bound Scam)

- Seam class – IV (Flat Seam)

- Seam class – V (Decorative Seam)

- Seam class – VI (Edge Neatening Seam)

- Seam class – VII (viii) Seam class- VIII

Collar: The flat, upright or turned over section of a garments which fits around the neck is called collar. There are three types of collar. Such as: (i) One piece collar ( ii) Two piece collar ( iii) Multi piece collar

Counter Sample: The sample which is followed by approved sample is called counter sample. For smooth production it is necessary.

Course Density: The numbers of visible loops per unit length measured along a wale is called course density.

Cuff: The lower part of the sleeve of a garments and also the corresponding part of trouser and gloves is called cuff. There are four types of cuffs. Such as: (i) Square cuff ( ii) Round cuff ( iii) Pointed cuff and (iv) Notched cuff

Cutting: Process during which separate garment components are cut out from a single fabric ply or a fabric spread in accordance with the shape and number determined by the marker.

Cutting room: Separate area in a production enterprise where garment components are cut out.

Dart: The process to give respected shape by removing the wedge from the garments surface by stitching or cutting and stitching is called dart. It is used for tightness of goods.

Disposable Garments: The garments which are not used further after using ones i.e. the garments which are used thrown after using are called disposable garments.

Drape: The ability of a fabric to hang graceful folds is called drape. Example : The sincisoidal type folds of a certain or skirt.

Drag knife: Knife with a slanting blade which is dragged along the profile of the cut component during the cutting process.

Drill marks: Round holes placed in the area of cut components to show ends of darts and placement points of ‘put on’ components (patch pockets, flaps, others).

Dummy: The model which is exactly similar to the shape of the body of a man and which is used to check the fitting of garments is called dummy.

End catcher: Device used with a spreading machine to fix the end of the laid material ply not allowing it to move from its correct position.

Export documents: The documents which are to be submitted by a C and F to the customs authority for exporting goods are called export documents. These are given below:

- Shipping bill of entry

- Export L/C

- Packing list

- Insurance

- UD (Utilization Declaration)

- VBF- QA from to supply by the C and F agents.

- Export permission from EXP.

Face: Correct or better-looking side of a fabric.

Flap: The part which is used to cover the opened face the pocket is called flap.

Fore Part: The front parts of the garments which are used for covering the upper part of the body is called fore part.

Fullness: An extension to the length on one of two section of a garments joined by a seam, used to create volume or shape in the garments is called fullness. In simple words, for getting respected shape, some extra fabrics are used in the fore parts of the garments. This shape which is got by using some extra fabrics is called fullness. Example: Sleeve head.

Fusing: Process during which cut components or their blocks are fused with interlinings coated with thermoplastic resin. Fusing certain garment components is performed to create strength and stability of the garment, improve its shape and increase resistance.

Grading: It is the process to make pattern of different sizes from master pattern.

Grain Line: Pattern pieces normally carry a line is called grain line.

Grain: The term which is used in making up to refer to the direction of the warp threads is woven or warp knitted and the direction of Wales in knitted fabric is called grain.

Grinning: The defect in a compound structure (e.g. a double cloth ) in which one fabric can be seen through the other is called grinning.

Hang Appeal: The garments which are hanged on hangers or kept on hanger during selling, how much beautiful to see in that condition is called hanger appeal.

Hanger: The substance by which garments are hanged is called hanger.

Hem: The raw edge is turned under or over and sewn to neaten the edge of the garment, such as the bottom edge of a shirt.

Hook and Loop Fastening: A Swiss invention made this product. This items consists of two nylon tapes, one having a surface of loops and the other surface of hooks. When pressed together, two tapes adhere and cannot open by side way turn but easily open by upwards turn.

Import Documentation: The documents which are to be submitted by a C and F agents to the customs authority for realizing imported goods from the ports is called import documentation. These are:

- Bill of entry

- Copy of bill of lading (BL)

- Copy of invoice

- Packing list

- Certificate of origin (CO)

- UD/UP ( Utilization Declaration / Utilization Permission )

- Copy of master L/C

- Letter of credit authorization (LCA)

- Performa invoice

- Copy of insurance cover note

- PSI (Pre- shipment inspection)

- Any other documents.

In other words, a straight line marked on a pattern pieces to ensure warp or wale direction to ensure the pattern pieces is correctly positioned and cut to achieve the appearance in the finished garments is called grain line.

Initial marker: Marker in which pattern pieces are placed in a logical way with allowances around them to achieve the required precise pattern matching of the components directly on to the fabric later.

Inlay: The extra fabrics which are kept with pattern after all removing seam for making greater of any parts of the garments in need is called inlay.

Inset: The pieces of fabrics which are in fining or which is used to increase the beauty of cloth is called inset.

Interlacing: During stitching when one loop of the one thread passes over another loop of another thread is called interlacing.

Interlining: Interlining is one kind of accessories which is used between two layers of fabric in garments to support, reinforce and control areas of garments and to remain actual shape. It is two types. Such as: (i) Non Fusible/Sewn Interlining (ii) Fusible Interlining

Interlooping: When loop of one thread passes through the loop of same or another thread is called interlooping.

Invoice: The documents mentioning the price is called invoice. After sending the garments goods to the importer country it is to the buyer for collecting price.

Jigger: It is one kind of button which are used in the inner side of the garments.

Lace: Openwork fabric, patterned with open holes in the work, made by machine or by hand plaiting, knotting, looping, or twisting.

Lay planning: Process during which two or more different garment sizes are combined in every marker, the number of fabric plies in every spread and the number of spreads laid down for every marker is determined.

L/C: L/C means is Letter of Credit. It is a commitment by opening a bank on behalf of the importer of the exporter that the bills drawn by them on the importer countries covering the shipment of specified items and quality of goods within stated period will be in charge of documents under certain terms and condition.

Ligne No: The measuring unit of the bottom which indicates the diameter of the button is called ligne no, If diameter increase then ligne no is increased.

Ligne: A standard measure equal to 0.635 mm by which buttons and ribbons measured is called ligne.

Lining: The cloths which are used to cover the part or all of the inside of apparel, the back of curtains or the inside or back of the other product is called lining. It is generally a functional part of a garment, an accessories. Lining materials can be used for small parts pockets and for complete garments, either fully bagged out. It can be used coat, jacket and rain coat, body and sleeve for ladies items. Such as: Blouse, frock etc. It is attached by sewing, coating is not used.

Making Up: The process of transforming fabric to garments is called making up.

Marker: Efficient layout of pattern pieces. It can be used in manual or automated cutting to minimize consumption and organize the cutting process.

Model: The designers original sample garments is called model.

Motif: The decorative figures of a pattern is called motif. These may be cut out and applied to a garment for ornamentation.

Nap: Prominent direction in which surface fibers lie on a fabric.

Non- Quota: The categories or items which are for exporting without any condition or limitation, these are called non-quota.

Notches: Short cuts at the edge of components which help to join components correctly and precisely during the sewing process.

Objects of Cutting: To separate fabric parts from the spread of the lay according to dimension of marker for the purpose of garments making according to the pattern pieces.

Off Grain: If any weft yarn of fabric do not states in 90 degree angle with selvedge, is called off grain. In other words, if grain line of pattern piece is not placed or cut parallel to grain line of fabric is called of grain.

Oscillating (reciprocating) knife: Type of knife whose blade achieves cutting action through a push and pull reciprocating motion.

Overall marker: Marker in which all pattern pieces of one or more garments are positioned in a free arrangement to obtain minimal fabric utilization.

Pattern: Design or style of a printed, woven or knitted fabric, e.g. stripe, check, floral.

Pile: Raised surface of a fabric. It can be either cut or loop, patterned or plain, textured of flat.

Pin tuck: A narrow fold/pleat secured by topstitching which provides a decorative feature on a garment.

Pleat: The folds usually run in the lengthwise direction of a garments giving a decorative effects and allowance for expansion of the garments in the cross section is called pleat. It is used for looseness of garments. Dart and pleat are all used of fashion designer in the back Part of a shirt.

Ply: Piece of fabric laid in a spread in accordance with the spreading mode and fabric pattern. Its length corresponds to the length of the marker.

Point: The most visible place of the chest is called bast point.

Pressing: The process to remove the unwanted crease and crinkles from the fabric to give it smoothness, lusterness, and the appearance is called pressing. It is known as ironing in garments industries. There are for types of pressing like as follows :

- No Pressing

- Minimum pressing

- Under pressing and

- Permanent pressing

Puckering: The wrinkled appearance of a fabric in which non- uniform relation or shrinkage has occurred is called puckering.

Quality Control: Quality control is the checking verification and regulation of the degree of excellence of an attribute or property of material.

Quality: The nature, kind or character of any material is called quality.

Quota: A certain amount of garments goods which are allowed to be exported by manufacturing country to the imported country is called quota.

Raw edge: The edge of the fabric that is not stitched or finished.

Router: Cutting tool which rotates around a vertical axis during cutting and allows movement along the profile of the cut component.

Sample Garments: The garments which are made by manufacture according to the given design of buyer and which are sent to the buyer for approved to know whether it is according to the dimension or not called sample garments.

Scye: The measurement of arm hole is called scye.

Seam Pucker: Unwanted waviness of the material along the seam line is called seam pucker. This may be apparent immediately after sewing or it may develop later in use.

Seam Strength: The strength of seam is called seam strength. It depends on:

- Strength of thread used

- Unbalanced stitch

- Stitch density

- Seam type

- Size of stitc

Seam Types: Arrangements of fabric ends at the seam line is called seam type.

Seam: The joining between two or more pieces of material is called seam.

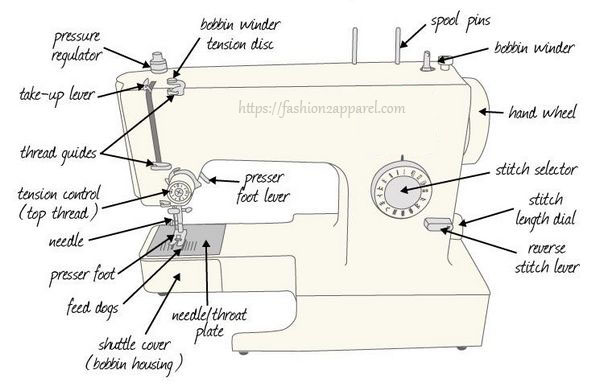

Sewing: Sewing is the process to join up the different parts of the fabric with the help of sewing needle and threads in manually or by sewing machine.

Splice lines: Two lines marked at every splice place in the marker. In the case of fabric faults, the zone between the splice lines is the area where the fabric is laid double (overlapping) to obtain all cut components in their full shape in either the first or the second piece of fabric.

Spreading: Process during which fabric is cut in certain length pieces and placed one above other in one or many plies.

Stitch bight: The distance between the inner edge of the stitch and the adjacent edge of the stitch. This term is commonly used to describe the Overedge stitch width.

Stitch Density: The product of wale density and course density is called stitch density.

Stitch: Loop or loops of one or more threads bounds with each other, either by interlacing, interlooping, intralooping or combination of those when sewing fabric, each unit of such configuration is called stitch.

Tack: A temporary stitch to hold pieces together, usually removed after final stitching. Tacking is frequently referred to as basting.

Trimming: The attachment of various decorative effects without fabric but including thread, button, interlining, zipper, main label, care label, size label etc called trimming. It is used to ornament the fabric.

Topstitch: Exposed stitching which is sewn a uniform distance from a load-bearing seam. Mainly used to strengthen the seam and give a decorative appearance. Topstitching can be done in the same or contrasting thread, depending on the desired decorative effect required.

Types of Feed Mechanism:

- Drop feed mechanism

- Differential bottom feed

- Adjustable top feed system

- Needle feed mechanism

- Unison feed mechanism

- Puller feed mechanism

Types of L/C:

- Master L/C

- Back to back L/C

Master L/C: When a L/C is opened to import the goods from exporter to the buyer is called master L/C.

Back to back L/C: When a L/C is a opened against master L/C to import or called raw materials to produce and supply the garments is called back to back L/C.

Tubular fabric: Fabric in a tubular form knitted on a circular knitting machine.

Wales: Columns of loops along the length of a knitted fabric.

Wale Density: The numbers of visible of loops per length measured along a course is called wale density.

Warp: Lengthwise threads in a fabric attached to a loom before weaving begins.

Weft: Threads width ways in a fabric as woven.

Welding: Welding is the process in garments manufacturing which involve the sealing together of thermoplastic materials but the heat is not applied externally.

Works Aids: The extra m/c parts which may be attached to speed up the production and improve quality in the sewing m/c are called work aid.

References:

- Guide to Basic Garment Assembly for the Fashion Industry by Jayne Smith

- Industrial Cutting of Textile Materials By I. Viļumsone-Nemes

- Garments Merchandising by Prof. M.A. Kashem

- Practice of Garments Merchandising and Management by Faruk Hasan

Editor of Fashion2Apparel. She is a fashion designer and ex-lecturer in Fashion Designing. She wants to spread fashion knowledge throughout the world.