What is Garment Joining?

In the last stage of garment manufacturing, different materials are combined to form the final product. Based on the construction of the product, the appropriate manufacturing steps to combine the garment components have to be chosen. Garments are made by joining several patterned substrates together. These substrates can be various types of woven or nonwoven fabric that are joined together or to accessories that could include linings, buttons, zippers, tapes, and decorative pieces. Representative examples are as follows: Laminating of textile fabric and membranes to form barrier textiles. In such processes, different layers are bound together through combination of reactive binding systems or hot-melt glue, with the aim to build a water-tight barrier. Such textiles exhibit a textile surface at their outer side and show excellent water tightness through membranes inside the layered structure.

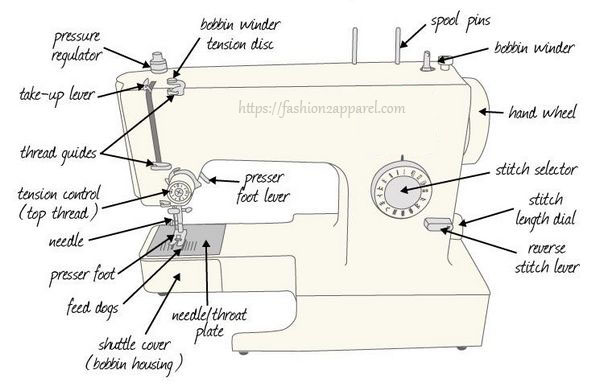

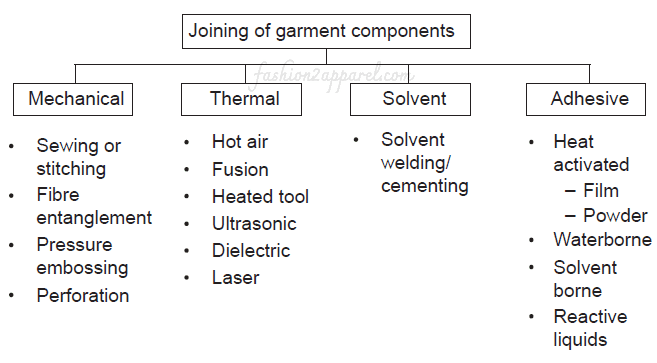

Today, the most dominant method of joining these materials is by sewing or stitching. Sewing represents the standard process to join flexible textile materials by stitching. The stitches can be formed by regular crossing of two or more threads. Based on the expected mechanical properties, a seam can be constructed as very rigid or highly elastic joint. Even in a simple pair of jeans, more than six different types of sewing are combined. In addition to sewing, numerous other joining methods are available for garments. They can be categorized by the basic mechanisms that bring about the joining, as shown in below Figure.

In sewing every stitch perforates an in initially water-tight structure; thus for applications where water-tight sewing is required, a conventional seam is covered by a tape that then seals the sewing tightly. In addition, thermal bonding, for example, based on ultra-sonic sewing machinery is in use.

Alternative Methods of Joining in Garment Manufacturing:

Garment manufacturers are developing innovative clothing designs that are placing significant and critical demands on the way garments are joined. Manufacturers are also facing increased economic and environmental pressures to increase processing speeds, lower costs, add value to finished products, and amortize capital equipment over more than one use. As a result, these manufacturers are seeking new and alternative methods for joining garments.

The process which have been developed as alternative to sewing are known as alternative methods of joining. The alternative methods next to sewing include adhesive bonding, conventional thermal (e.g., hot air and heated tool) welding, and advanced thermal (e.g., ultrasonic or laser) welding. Generally below alternative methods of joining are widely used instead of sewing:

- Welding

- Adhesive

- Moulding

- Fusing

A. Welding:

Welding is the process of garment manufacturing which involve the sealing together of thermoplastic materials but the heat is not applied externally. In thermal-welding processes, adhesion occurs by melting the substrate surfaces so that they flow into one another and then set on subsequent cooling. Heating can be achieved using a range of different methods such as conventional external heating sources, dielectric or high-frequency welding, ultrasonic welding, and laser-assisted welding.

Basic procedure of the method:

Heat applied on the fabric

↓

Melting of thermoplastic materials

↓

Applying pressure on melted material

↓

Creation of bonding

↓

Cooling

↓

Fabric joined

Amount of heat generation depends on:

- Amplitude of frequency.

- Frequency.

- Pressure.

- Time of frequency.

Advantages:

- Water cannot penetrate into seam or joining.

Disadvantages:

- Used in less costly garment.

- Used in the fabric where amount of thermoplastic is 65%.

Uses:

- Sealing of edges of seams and fabrics.

- Shaping of different component of garments.

- Production of different component of garments.

- Produce button hole.

- Cutting and sealing of length of ribbons.

- Attaching motif of the garment.

- In water proofing seams.

B. Adhesive:

The term adhesive is used to mean a substance which is sticky in the conventional sense of the word. But it is used for joining the fabric. Adhesives can set or cure by carrier (solvent or water) evaporation, chemical reaction, or thermal activation. Chemically reactive adhesives solidify primarily by a chemical reaction of one or more components in the adhesive formulation. It should be noted that solvent welding cementing processes or solvent-borne adhesives are in disfavor due to environmental, safety, and health concerns and regulations. As a result, waterborne adhesives and heat-activated adhesives are replacing solvent-based adhesives in many applications.

Types of Adhesive:

- A coating of thin adhesive film on silicon paper which is transferred to the fabric and the plies of the fabrics become joined.

- A material which melts on applying heat and helps in joining the fabrics.

Applications:

- The use of an adhesive thread as one of the looper threads which can be sewn in to the edge neatening of the hem.

- Used for water proof garments.

- Another use of adhesive is in seams which will take no stain.

C. Moulding:

By moulding method the required definite shape of garments is found without creating seam.

Basic procedure of the method:

The desired shape by shrinkage

↓

Heat apply

↓

Thermoplastic fiber in fabric become soften

↓

Cooling

↓

Desired shape

D. Fusing:

Fusing is a joining process of fabric. Fusing often serves as alternative to sew-on interfacing, which strengthens, supports and adds shape to fabric. During fusing an interlining is bounded to the outer fabric with the help of a thermoplastic resin.

Advantages:

- It offers reduction in direct labor and skills giving consistent quality.

You may also like: Stages of Quality Control in Garment Manufacturing Technology

Editor of Fashion2Apparel. She is a fashion designer and ex-lecturer in Fashion Designing. She wants to spread fashion knowledge throughout the world.