Enzymes in Textile Industry:

Enzymes are biological catalysts in the form of proteins that speed up chemical reactions in living organisms without being consumed in the process. Enzymes are a sustainable alternative to the toxic chemicals used in the fashion and textile manufacturing. Enzymes are rapidly becoming very important, especially in the spheres of sustainable technology and green chemistry. Enzymes carry out thousands of the metabolic processes that sustain life. They play crucial roles in various biological processes. Enzymes are used in a wide range of processes in the textile industry such as desizing, scouring, bleach clean-up, denim washing, biopolishing, etc. All enzymes are proteins and biodegradable. They enhance the rate of chemical reactions. Application of enzymes in the textile industry is one of the most rapidly growing fields in industrial biocatalysis. Enzymes play an increasingly important role in industrial wet textile pretreatment and finishing processes. Enzymes are very specific catalysts; they operate best at ambient pressures, mild temperatures and often at a neutral pH. Besides, enzymes are environment friendly which help to reduce impact on polluting solid waste, liquid effluent and gaseous emission. It ensure bio-degradable characteristics and save the environment; save water, energy and time; minimize effluent load, in terms of BOD, COD and TDS.

Enzymes plays important role in bio-processing of textile. Enzymes are there from nineteenth century but less than only two decades ago it was first used in textile processing. Enzymes increase the functionality by minimising the strength and effort. Chemical textile processing is already at hand from very first day, but that cause hazard. In place of that, enzymatic processing is bio-friendly, non-toxic, and trimming down the pollution rate generating due to textile processing. In addition with that, enzyme technology reduces the use of vast amount of water and causes the savings of most important part of ecosystem. Therefore, day by day enzymatic textile progression is getting worldwide appreciation to the manufacturers.

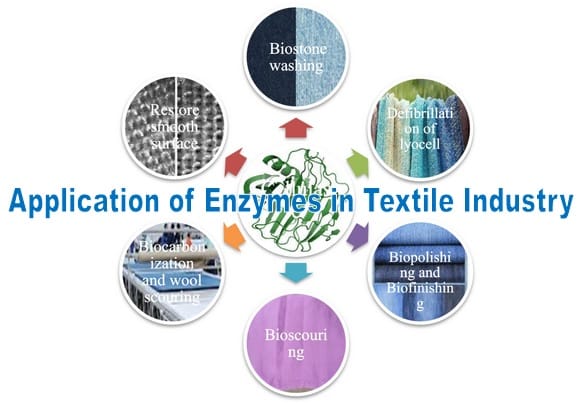

Application of Enzymes in Textile Industry:

There are different types of enzymes used in textile and garment manufacturing. For example, the enzymatic desizing of cotton with a-amylases is in practice for many decades. Various other enzymes are also being used since long in different cotton pre-treatment and finishing processes. The enzymes are also used for the processing of other natural fibers, e.g., enzymatic degumming of silk with sericinase, felt-free finishing of wool with proteases and softening of jute with cellulases and xylanases. The surface treatment of synthetic fibers such as polyester or polyacrylonitrile with enzymes has also been studied extensively.

List of enzymes and their application, benefits in textile industry are discussed below:

1. Amylase:

Amylase are used in desizing of cotton to improve speed, economics and consistency of the process. Use of thermostable enzyme, characterisation of the process, etc., are recent developments in the amylase applications.

2. Cellulase:

Cellulase enzymes are used in bio-polishing and bio-fading to removes surface fuzz (protruding fibers), surface pills (balls of entangled fibers) from cotton and viscose fabrics. Cellulase provides effective color fading of denim. Replaces pumice stone used to get characteristic abraded, faded appearance.

3. Catalase:

It neutralizes hydrogen peroxide and quenches residual peroxide. Reactive dyes are especially sensitive to peroxides and require extended rinsing and/or use of chemical scavengers.

4. Pectinase:

Pectinase is responsible for carbonization of wool, scouring of cotton and retting of flax. It degrades vegetable matter in wool. Replaces conventional treatment using a strong acid, followed by mechanical crushing. Removes pectineous impurities from cotton and enhances absorbency. Achieves rapid and uniform retting and avoids the risk of bacterial or fungal contamination which tends to occur in case of dew and water retting.

5. Laccase:

Specially it is used for denim finishing. It decolourises indigo dyestuff and enhances the apparent abrasion effect with little or no impact on cellulosic fibre strength.

6. Lipase:

It is used in desizing process to removes triglyceride-based size lubricants from fabrics.

7. Protease:

Protease are used in wool finishing and silk degumming process. It induces sand-washed effect on silk garments. It also enhances comfort (reduced prickle, greater softness), improves the surface appearance and pilling performance.

8. Xylanase:

It is used in scouring and bleaching to removes wax, color, residual seed coatings, etc., which otherwise inhibits the natural absorbency of the fiber and prevents subsequent dyeing, printing or finishing of cotton yarns and fabrics.

Conclusion:

There are several types of enzymes used in textile and garment manufacturing in the place of traditional methods. The application of enzymes is making the manufacturing process used for fashion and textiles more sustainable. These enzymes are being used mainly in chemical processing of cotton and its blends since long. Many of the fashion brands are adopting the enzyme application for various finishes. In future, many traditional processes will be replaced with enzyme applications.

References:

- Sustainable Textile Chemical Processing Edited by Javed N. Sheikh & M. D. Teli

- Sustainable Technologies for Fashion and Textiles Edited by Rajkishore Nayak

- Sustainable Apparel: Production, Processing and Recycling Edited by Richard Blackburn

- Advances in Functional Finishing of Textiles By Mohammad Shahid and Ravindra Adivarekar

Editor of Fashion2Apparel. She is a fashion designer and ex-lecturer in Fashion Designing. She wants to spread fashion knowledge throughout the world.