Defects in Garment Industry:

The inspection of semi-finished and finished garments is very important for quality control in the garment industry and plays an important role in the automated inspection of fabrics and garment products. Quality inspection of garments is an important aspect of apparel manufacturing and still relies heavily on trained and experienced personnel checking semi-finished and finished garments visually.

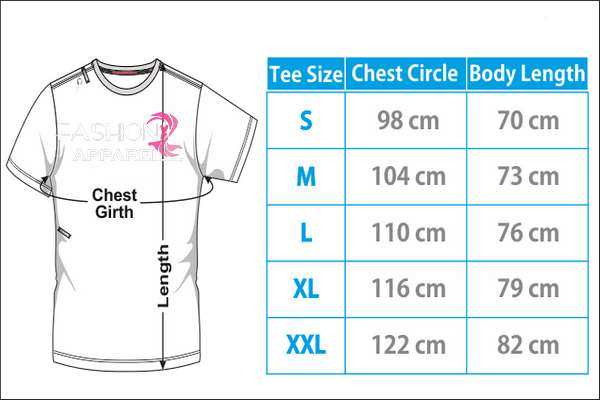

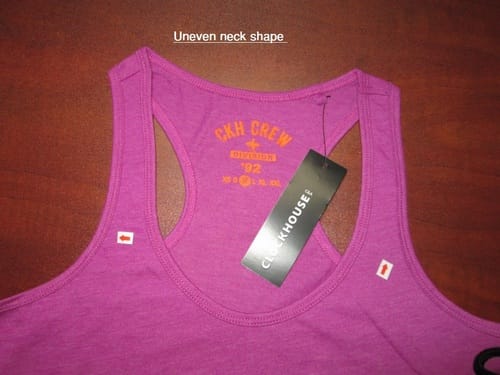

The most important factor in garment quality is the size and shape of the garment and stitching quality. Generally, the size and shape of the structuring element are determined by experience or trial-and-error, which is time-consuming and may not achieve a satisfactory performance, particularly when the size of the image is large or the image is analyzed in a real-time situation. Therefore it is necessary to develop a method to acquire the best structuring element of the morphological filtering for image analysis.

During production time different types of defects and problems are occur in garment industry. Different sections in garment industry are found variety types of defects such as, cutting defects, sewing defects, finishing defects etc. All kind of defects are mainly occurred by poor quality machine and untrained workers or operators in their working time. Every manufacturer wants to try to minimize these defects from their production. To minimize all of these defects, production manager maintain some remedy techniques and also try to arrange a training course for their poor skill workers and operators.

Defective products of services are produced for a variety of reasons. A few of them are given below.

Following Defects Occur in Garment Industry:

1. Not understanding buyer’s specifications or requirements.

2. Not understanding increasing requirements of the buyer.

3. Unsystematic work and non-compliance of work rule lead to major setback and defectives.

4. Defects caused by human or operator error.

5. An operator performing a job improperly causes a defect.

6. A worker missing an operation in the job makes a defect.

7. An operator setting a job improperly causes a defect.

8. An operator working carelessly may commit mistakes.

9. A worker hurrying or panicky causes defect.

10. A worker complying work rule causes defect.

11. A worker due to indiscipline may cause a defect.

12. A harassed or humiliated worker may cause defect.

13. Absenteeism of operators may cause defect.

14. Migration of worker may lead to poor quality.

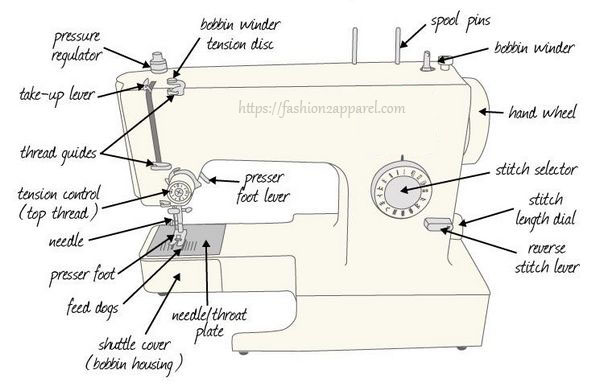

15. Machine not well maintained.

16. A machine leaking oil causes defect.

17. A machine blunt or broken needle causes defect.

18. A machine with untensioned thread causes defect.

19. A machine not properly cleaned causes defect.

20. A machine with wrong feed mechanism causes defect.

21. A machine with defective folder, attachment causes defect.

22. Using sub-standard materials causes defect.

23. Not inspecting goods prior to delivery may cause importation of shoddy goods.

24. Not importing goods from right suppliers leads to poor goods.

25. Not importing goods prior taking delivery at store.

26. Absence of work standard causes defect.

27. Absence of Quality Standard causes defect.

28. Absence of Maintenance Standard causes defect.

29. Absence of training of workers may lead to defects.

30. Lack of motivation or workers leads to defective work.

You may also like: Step by Step T-Shirt Measurement Techniques with Size Chart

Editor of Fashion2Apparel. She is a fashion designer and ex-lecturer in Fashion Designing. She wants to spread fashion knowledge throughout the world.