Garment Production Process:

The fundamental manufacturing process of the garment industry has not undergone much change over the past century, and is considered by the progressive bundle system. Work or operation is planned in a manner that each operator is specialized in one or a few operations. The fabric is first cut into various garment panels and then grouped by components of the garment, tied into bundles and sent to an assembling (sewing) section for making a garment.

To make a complete garment depends on some steps and techniques. Apparel manufacturing process starts from order receiving and end to the dispatching shipment of the finished garments. If we explain it, then it involves many processing steps like Product Design, Fabric Selection and Inspection, Pattern Making, Pattern Grading, Marker Making, Spreading, Cutting, Bundling, Sewing, Pressing or Folding, Finishing and Detailing, Dyeing and Washing, QC and finally ending with a finished garment.

In this garment production process flow chart, it helps to understand how raw materials are moved from one process to another process until they are resolved into the required garments.

For the large scale of garment production some processing steps or sequences are involved in the garments manufacturing technology. Here I will mention garments production flowchart, which should follow when you make a garments.

Flow Chart of Garment Production Process

Step by step garment production process are discussed in below:

Design/Sketch

(A particular style of design/ sketches with measurement mainly comes from the buyer to manufacturer.)

↓

Basic Block

(Basic block is an individual element of garments, which is created by without any allowance, style, and design.)

↓

Working Pattern

(Working pattern is made for a particular style with net dimension concerning the basic block along with allowance.)

↓

Sample Garments

(After making a sample, it is sent to buyer for approval to correct the faults and write comment on sample garments.)

↓

Approved Sample

(After re-correct the sample faults, it is again sent to buyers. If it is ok, then it is called approved sample.)

↓

Costing

(In this stage apparel merchandiser prepares a costing sheet for the buyer. Including fabric costing, cost of making (CM) charged, trimmings, profit etc)

↓

Production Pattern

(For bulk production making production pattern with allowance and net dimension.)

↓

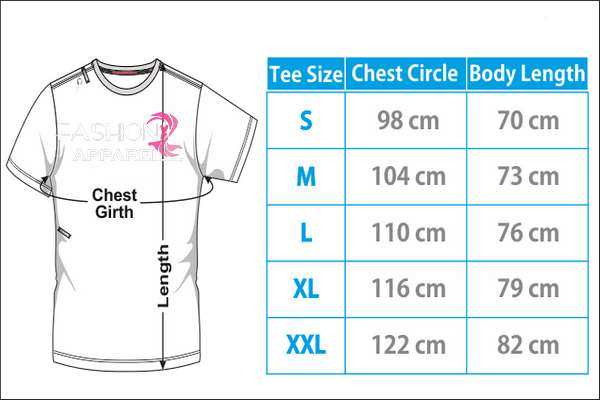

Grading

(Different size should be graded as per buyer requirement like S, M, L, XL, XXL.)

↓

Marker Making

(For a particular style of garments, marker is made with a thin paper which is contains all the components of different sizes.)

↓

Fabric Spreading

(In this stage fabric is spread on table properly for cutting. It is done by manually or computerized way.)

↓

Cutting

(Fabric cutting is done according to marker dimension.)

↓

Sorting and Bundling

(After the cutting sort out the fabric according to size and color and for each size make in individual bundles.)

↓

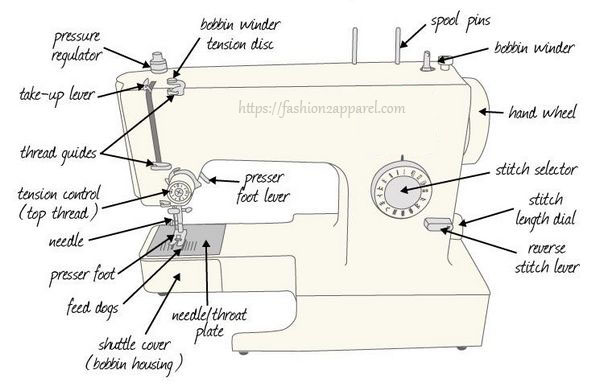

Sewing

(Sewing department is called heart of apparel manufacturing. In this section, assemble a full garment by sewing.)

↓

In-line Inspection

(This inspection is done at the time of production, so that any defect occurring at this time may be located at the earliest stage.)

↓

Ironing and Finishing

(After sewing process, this complete garments are send to finishing section for ironing and also other finishing processes are done like extra loose thread cutting, measurement checking, tag attaching etc.)

↓

Tagging

(All label and tags are attached with garments such as price tag, size tag, care label etc.)

↓

Final Inspection

(Final inspection is very important for an export order shipment. Different parts of garments are inspected in this stage such as garments main fabric, accessories, trims, label, fabric faults etc. Should be inspected as initial sample.)

↓

Packing

(Packing is done by buyer’s instructed Polyethylene bag. This process is done manually.)

↓

Garments Cartooning

(After packing, it should be placed in cartooning for export.)

↓

Dispatch Shipment

(Completely ready for shipment)

You may also like:

- Different Types of Production System in Garment Industry

- Quality Control in Cutting Department in Apparel Industry

- Step by Step Lay Planning in Cutting Room

Editor of Fashion2Apparel. She is a fashion designer and ex-lecturer in Fashion Designing. She wants to spread fashion knowledge throughout the world.

Hello. I found your newsletter when I was looking for a reference book about pattern -making for industry. The blog post on your site showed details of how to order, label and notch the pattern for cutting and sewing , I also saw where you have book for sale on the subject. If so, please let your subscribers know. Perhaps I had the wrong website.