What is Spin Finish?

A spin finish is a liquid or solid composition that is applied to the surfaces of man made fibers in order to improve the processing of such fibers in short-staple or long-staple spinning. Although a spin finish is a layer only a few molecules thick on the surface of the fiber, it is one of the most important variables dictating the performance, quality and uniformity of processing. The following terms are all used to define the same thing: spin finish, spinning finish, waxing, size, dressing, coating, fiber finish, spinning lubricant, agent, textile treating composition, textile treating agent and condition agent. Spin finishes are added as the last stage of the fiber production.

Spin finishes are the lubricant which provides surface lubricating, plasticizing and static protection to manufactured fiber. It is applied in fluid condition just before wind up. Spin finish is very essential for man made fibers for efficient processability and conversion to textile materials for different applications. It is a layer on fiber which can thick molecules on surface of the fiber.

Why Spin Finish is Essential for Man Made Fibers?

Fibers need to be treated with surface finishes or lubricants to allow high-speed processing. The various processing steps such as drawing, bulking, and textile processing would be impossible without these spin finishes because so many of them rely on specific frictional properties of the fiber (for example, friction twisting).

During mechanical processing of fibers and fabric production, a lot of tension and friction is applied to the material. As a result of the high friction and abrasive stress, a number of negative effects appear, which are as follows:

- Undesired temperature increase of fibers and yarn

- Yarn breakage and machine stops, leading to lower product quality

- Uncontrolled yarn tension during fabric formation, leading to crease formation and shrinkage

- Electrostatic charge that leads to ballooning of multifilament yarns and adhesion to machine parts

- Development of fiber dust leading to machine failure.

Thus, it is important to prevent such effects and to control fiber friction and yarn tension during processing and to maintain well-controlled yarn tension during fabric production. Besides accurate control of climate (temperature and relative humidity) to stabilize the respective fiber properties, specific auxiliaries are also added on the fibers and yarn.

Objects of Spin Finishes for Synthetic Fibers:

- To lubricate yarn.

- To reduce static electricity.

- To increase the cohesion of the yarn.

- To plasticize the fiber.

- To keep law volatility

- To reduce yellowing

- To keep thermal stability

- Helps to handle variation, i.e. slick, soft, scoop all controlled by choice of lubricant

Different Types of Spin Finishes for Manufactured Fiber:

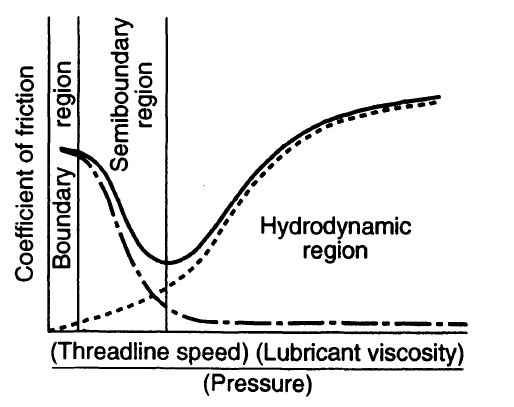

I) Lubricants: Used to control the friction of the fiber.

Example: Oils, polyglycols, ester of fatty acid.

II) Plasticizers: Plasticizers make the fiber more flexible by reducing the glass transition temp and also reduce brittleness.

Example: Dibutyl, Silicate esters, Silicate.

III) Antistatic agents: Antistatic agents are hygroscopic chemicals which can conduct the static charge from fiber to air or earth to improve dielectric const and to reduce co-efficient of friction.

Example:

- Inorganic salt (such as lithium chloride)

- Ester of fatty acid (Butyl stearate)

- Alcohols, amide (NN-dihydroxy ethyl stearamide)

- Poly oxyethylene derivatives etc.

IV) Bactericides and

V) Antioxidants.

Properties / Requirements of Spin Finishes:

The primary functions of a spin finish are to provide surface lubrication to the fiber/filament, antistatic action and good fiber-to-fiber cohesion. In order to perform these functions, a spin finish should have the following desirable properties:

1. It should provide good lubricity to reduce the fibre-to-metal (F/M) friction in order to prevent fiber abrasion and maintain low, uniform tension during processing.

2. It should reduce the static charge build-up during processing.

3. A balanced degree of cohesion is necessary, as too much lubricity may cause fiber slippage resulting in package distortion in winding and other operations.

4. It should have a controlled viscosity range; too Iowa viscosity causes difficulties in slinging and low yam frictional values, while too high a viscosity causes excessive add-on coupled with high frictional values.

5. For consistent viscosity, the spin finish must be resistant to bacterial growth; it also should not form insoluble resinous compounds in the presence of oxygen.

6. Scourability (ease of removal): poor scourability would cause dyeing problems and potential soiling spots.

7. It must be corrosion resistant and should not cause damage to rollers, guides or needles.

8. It should be non-allergenic, non-toxic and ecologically acceptable.

9. Spin finishes are generally applied in emulsion, hence they should beeasily emulsifiable.

Other properties of spin finishes:

- To lubricate the filament for controlling the friction.

- It should have anti static properly.

- It must be provided with cohesiveness to the filament.

- It should not be oxidized in the air.

- It should give stable emulsion.

- It should not be carcinogenic.

- It should have good wetting property.

- It should be non- toxic.

- It should be cheap and easily available.

- It should not affect dyeing or finishing process.

- It should be chemically inert.

- It should not object able color or odor.

You may also like:

- Essential and Desirable Properties of Textile Fibres

- What is Flax Fiber | Properties and Uses of Flax Fiber

Editor of Fashion2Apparel. She is a fashion designer and ex-lecturer in Fashion Designing. She wants to spread fashion knowledge throughout the world.