Garment manufacturing process is a complex and multi-step procedure involving various stages from the design to the final product. It is labor intensive, low wage industry but a vibrant, innovative sector. Manufacturing process of garment industry work commences after receiving finished fabric from the dyeing or finishing (Processing) industry. Once the fabric is received, the following activities are performed to manufacture the apparel from the fabric is given below.

Step by Step Garment Manufacturing Process

Receipt of order from the customer

↓

Interpretation of the technical specification sheet and evaluation of the requirement

↓

Production schedule and target calculations from Industrial engineering and Production planning departments

↓

Activities related to the cutting department: Marker planning, spreading, marker making, cutting, bundling and stickering

↓

Value added activities: Embroidery, printing and fusing activities in the cut components

↓

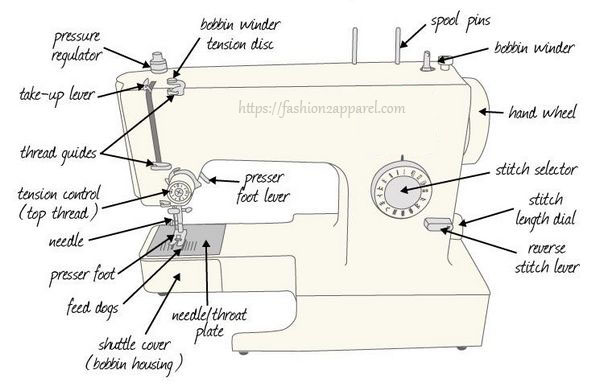

Sewing department: Sewing of cut components into a garment through a sequence of sewing process

↓

Checking and Pressing: Sewn garments are checked for defects, altered and pressed with hot iron to remove wrinkle

↓

Packing: Accessories are attached. Retail packing and commercial packing are done as per customer needs

↓

Shipment: The packages will be transported to the shipment yard and costs associated with it are calculated

Above steps are briefly described below:

The first process in the apparel industry is fabric cutting. The cutting department receives fabrics from the processing industry, which are dyed and finished as required by the customer and cuts into garment components. To prepare cut components into bundles or individual parts, the cut components are passed to the bundling department and passed to the sewing department. As a first process, the received fabric is relaxed to avoid unwanted shrinkage after manufacturing. During this relaxing process, the operators also check for any defects. Once the fabrics are checked, they are taken to the cutting table for the spreading process. In spreading, the fabric is spread on a table (cutting table) according to the marker plan and then cut into garment components.

The cut components are then transferred to the second department which is sewing, in which the components are sewed together and simultaneously checked manually for sewing defects either by random checking or by 100% checking process. The assembled garments are then passed to the trimming and checking department. In this department, the unwanted sewing threads protruding from the sewn parts are trimmed and again checked for general defects including fabric defects, sewing defects and stains. The next department in line is pressing, where the sewed garments are steam ironed to remove unwanted wrinkles formed due to the handling. After pressing, the garments are moved to the packing process. In this process, as instructed by the customer, packing accessories like price tag, brand tag, wash care label, etc. are attached to the garment and packed in the specified manner for retail sale purposes. Similarly, the garments are also packed in carton boxes for shipment and transportation purposes.

As it is observed, every operation in the apparel manufacturing industry involves a lot of manpower to convert the fabric into garment along with required machinery and other indirect costs and activities.

References:

- Handbook of Textile and Apparel Costing by Rathinamoorthy, Surjit and Vishnu Vardhini

- Apparel Manufacturing Technology by T. Karthik, P. Ganesan, D. Gopalakrishnan

- Garment Manufacturing Technology Edited by Rajkishore Nayak and Rajiv Padhye

- Garment Technology by M.A. Kashem

- Practice of Garments Merchandising and Management by Engr. Md. Faruq Hosen

You may also like: Flow Chart of Apparel Production Process

Editor of Fashion2Apparel. She is a fashion designer and ex-lecturer in Fashion Designing. She wants to spread fashion knowledge throughout the world.