Dyes in Textiles

Dyeing is one of the most essential processes in the textile industry. Besides, dyeing textiles is one of humanity’s oldest crafts. In the textile industry, dyes play a crucial role in enhancing the aesthetic appeal, performance, and value of fabrics. Various types of dyes are used in textile processing, depending on the fiber type, fabric construction, and the desired end-use. Each dye type has unique characteristics and application methods.

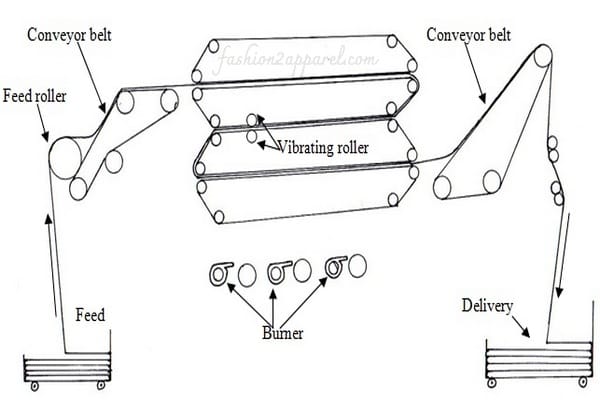

Fabrics can be submersed in dye so that both sides of the fabric absorb the color or it can have color placed onto one side of the fabric. Often, the latter process is carried out to produce a pattern – frequently with more than one color and usually using a variety of printing techniques.

The coloration of fabric can be completed at any stage of the production process; the fiber, the yarn or to the finished fabric. However, if dyeing is completed during the fiber or yarn stages, one must ensure that the dyes can withstand further processing – whether chemical or physical. With woven or knitted fabrics, care must be taken with the amount of elasticity present in the fabric because too much elasticity may distort color prints; warp has less elasticity than weft. When coloring fabrics, any previous finishing processes must be removed because they will distort the colors. Desizing, scouring and bleaching can remove the chemicals applied during the finishing process, create natural color and make the fabrics receptive to the dyes.

With synthetics, the melt polymer can have the dye color added before extrusion; this is known as mass coloration. The process provides permanent color, but one must ensure that the dye can withstand the temperatures involved with molten polymers. Some acrylics can be gel-dyed; after extrusion, the fibers are coagulated in a salt bath, which swells the fiber, and then they are submersed into the dye bath; the swollen fibers have high absorption. Polypropylene must be dyed during the fiber production stage in mass coloration because it cannot be dyed as a fabric.

The main aim of the dyer is to ensure uniformity of color, accurate color, as specified by the customer, and color fastness, as determined by the use of the end product. Color fastness is the resistance of color change when the colored material is subjected to a particular set of conditions.

The assessment is based upon numerical scales:

- Scale 1–8 for Light fastness: used on car interiors light fastness to 8. Carpets, upholstery and other soft furnishings light fastness to 6. These are measured on the blue scale system.

- Scale 1–5: All other agencies e.g. washing are measured using grey scale.

- Scale 1–5 for Staining; known as greyscale, but 5 is represented by two identical white samples, and 1 is represented by a white against grey sample.

Dry atmospheres are better for light fastness against UV light and fading. The darker the shade, the better deep light fastness it will possess; light shades have worse light-to-light fastness.

Note that, in the textile industry, the majority of fabrics are constructed in greige, which is an off-white color. The rolls of fabric are then dyed according to the product manufacturer’s requirements. This is a more cost-effective method of manufacturing because colors are often fashion orientated in apparel, soft furnishing trends and industrial applications so need to be dyed or printed by meterage on demand.

Types of Dyes and Their Application in Textiles

Here’s a simple overview of the major types of dyes and how they are used in the textile industry.

There are two categories of coloring fabrics: dyes and pigments, which are placed into three groups:

Group 1 These dyes:

- Are soluble: it can be dissolved in water.

- Cannot dye to maximum fastness when subjected to wet treatments; they may bleed.

- Are a one-step process as the dye contains a fixing agent such as sodium chloride (salt), citric or acetic acid.

Group 2 These dyes are:

- Non-soluble: in the final colored product the dyes are not soluble in water.

- Color fast: dyed materials are color fast when subjected to maximum wet treatments.

- Two-step process: entails dyeing the fabric and then adding a catalyst to fix the dye which may be a chemical or heat.

Group 3:

These are pigment dyes; pastes made from pigment with resin or glue that are applied to the surface of the fabric, dried and then baked or cured. Therefore, they do not penetrate the fibers. The prints are harsh, and the fabric handle is similarly harsh although softening agents can be placed in the paste to soften the handle, but they attract dirt. The advantage to pigments is that they do not require the washing process to remove excess dye. Pigment dyes are used mainly in printing (upholstery, largely), but they may rub off the surface or the resins used break down. The production process usually entails the mass coloration of man-made materials or resin bonding prints on all fibers. Pigment dyes are used across all fiber types for textile printing, especially in t-shirts, fashion wear, denim, and home textiles, offering bold colors, vintage effects, and ease of application in various printing techniques.

GROUP 1 DYES

Acid Dyes:

Acid dyes are usually made out of a sodium salt of carboxylic, phenol or sulphuric organic acid which fix to the fibers through hydrogen bonding giving bright and heavy colors. There are three classes that relate to fastness requirements, dyeing properties and economy, but they overlap and the choice to be used would depend upon the type of fiber and method of dyeing process:

- Equalizing or Levelling Acid Dyes – they have the highest level of dyeing properties, but they have a low wet fastness and are not usually used for clothing.

- Milling Acid Dyes – they are one color only, and they have a medium to high wet fastness but pale shades have poor light fastness.

- Metal Complex Acid Dyes – they have the highest wet and light fastness and are very economical to use, but they provide only dull shades.

Acid dyes are used on protein fibers, including wool, mohair, cashmere and silk plus polyamide.

Recipe for acid dye:

- Use approximately 750ml of water per 25 grams of fiber/fabric in a solution of 2 teaspoons of white vinegar and 100 grams of salt to 1 litre of water.

- Ensure that the fabric is clean or degreased; otherwise, the fabric will not dye evenly.

- Soak the fabric thoroughly for ten minutes in the salt, vinegar and water solution.

- Remove the fabric, squeeze the excess moisture from the fabric, and add the dye solution to the liquid. Return the fabric to the solution.

- Heat the liquid to 40⁰c (hand hot). Remove from the heat and let it stand for ten minutes.

- Stir gently for 5 minutes, reheat the solution, and let it simmer for twenty minutes, stirring occasionally, until the desired color is achieved.

- Allow it to cool and rinse it well.

Metal-Complex Dyes:

The dye molecule has a type of metal, such as chromium, cobalt, iron, copper or nickel, which dulls the shade. The ratio is 1:1, which has a low pH (2—2.5), or it is 1:2 (1 metal:2 dye), which has a higher pH (4–4.5) and is more environmentally friendly. These dyes are used for wool, mohair, cashmere, silk and polyamide fibers.

Direct Dyes:

They are used on cellulosics: cotton, linen, viscose and lyocell. As the name suggests, this dye provides direct color without the need of a mordant. These dyes may require salt to fix the dye into the fabric, or one may use copper or formaldehyde to ensure good adhesion. They are fairly colorfast to laundering. Most of these dyes are banned because of the chemicals involved and the fact that they are not eco-friendly in the disposal of the waste solutions.

Basic Dyes:

They are used on acrylics to produce bright shades. Acrylic is difficult to dye because the thermoplasticity of the fiber occurs at a low temperature. At 80ºc—85ºc, acrylic begins to change; therefore, the rate of the rising temperature of the dyeing process is slowed down and then sped up again. Sodium sulphate or acetic acid at a temperature of 100ºc is added to make the dye bath slightly acidic. These additions ensure that the fibers do not decompose, and they aid the uptake of the dye to the fiber. These dyes can be used on paper and, occasionally, wool and silk.

Disperse Dyes:

They are used on polyester, acetate, triacetate, acrylic and polyamide, but the color fastness is not good on acrylic or polyamide. The dyes are finely ground and mixed with a disperse chemical in paste or powder form that is water insoluble. The dyes are applied as an emulsion, often in a pressurized dye bath that is 130ºc, to disperse the dye into the fiber.

GROUP 2 DYES (Non-Reversible)

Vat Dyes:

They are used for cellulose-based fibers: cotton, linen, viscose and lyocell. The name comes from the large vats that hold the dye, and is one of the ancient forms of dyeing; this method was often used to dye materials indigo. Vat dyes are used for fabrics that require a solid, even shade of color or one color but using a resist dye technique such as tie-dyeing. The dyes require a second process to gain their true color; the dye is soluble in its reduced form, which is oxygen free, the fabric is then submersed in liquid for a while before being removed from the dye bath. The oxygen in the air transforms the dye into a water-insoluble, oxidized form, which changes the color. A prime example of this is indigo: when submersed, the fabric is yellow, but oxidization changes its color to blue. Today, indigo is produced synthetically, and other vat dyes are not particularly eco-friendly due to the manner in which they are disposed. A variation on this process is using a vat dye that requires light to change color; this is called Ink-O-Dye.

Sulphuric Dyes:

They are used on cotton, linen, viscose and lyocell, and they are fairly inexpensive. The chemical is usually sodium sulphide or sodium hydrosulphide which is added to the dye bath and fixed into the fiber or fabric via oxidization. Sulphur dyes are usually used for dark colors, such as black, (the most common form of sulphur dye), brown and dark blue; used with indigo to produce denim jeans. However, the waste from the sulphur is not eco-friendly, so glucose may be used instead. Although these dyes do not bleed in water, they are vulnerable to crocking (rubbing), bleach and chlorine.

Azoic or Azo Dyes:

They are used on cotton, linen, viscose and lyocell. These dyes are formed from two compounds, A and B. Compound A is placed on the fabric, and compound B is added on top, which causes it to react with A and form an insoluble dye. There is a limited color choice because the color depends upon the type of reaction that occurs, but the colors are very rich and include vibrant reds, yellows and oranges. However, these dyes are not eco-friendly; some of the dyes, when they break down, become carcinogenic. Consequently, two hundred of these dyes are banned by the EU!

Chromic Dyes:

They are also known as synthetic mordant dyes which are used on wool. Chrome with dichromate dye has good colorfastness, but nowadays it is being replaced with reactive dyes.

Reactive Dyes:

These dyes chemically react with the fiber, forming a strong bond. They are widely used for bright, colorfast shades in fabrics like t-shirts, bed linens, and home textiles. They are used on cotton, linen, viscose, lyocell, wool and silk. The dye contains a group that reacts when used in a weak alkaline dye bath. It forms a chemical bond with the cellulosic fiber, but there is dye wastage because the solution becomes weaker with use. This is the type used in the home and at schools and known by the trade name Dylon.

Natural Dyes

Natural dyes are colorants derived from plants, minerals, or animals. They are used to dye natural fibers like cotton, wool, and silk through eco-friendly processes. Commonly used in traditional textiles, crafts, and sustainable fashion, natural dyes offer soft, earthy shades and are valued for their biodegradability and non-toxic nature.

Traditionally, fibers and fabrics were colored using natural dyes which were produced by extracting the liquor of boiled plants, fruits and vegetables. Some of the dyes were not particularly color fast, so mordants were added to the dye bath to fix them into the fabric.

Conclusion

Choosing the right dye depends on the fabric type, desired color, and durability requirements. While some dyes like reactive and vat dyes offer excellent colorfastness, others like direct dyes are more economical but less durable. Understanding different dyes and their applications helps manufacturers produce high-quality, vibrant, and durable textile products.

Editor of Fashion2Apparel. She is a fashion designer and ex-lecturer in Fashion Designing. She wants to spread fashion knowledge throughout the world.