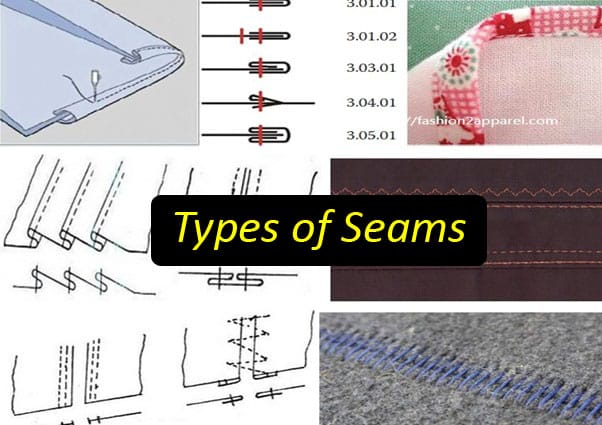

Basic Concept of Seam in Garments:

Seam is the combination of stitches which make line to join two ply of fabric. Basically seams are used as functional purposes. Some time used as decorative purposes. Seams are widely used in modern mass-produced apparel, footwear, house hold textiles and sporting goods which are sewn by different industrial sewing machines. Seam may be hundred types and these types are classified into eight main classes. In this article I have explained 8 types of seams with uses and figure.

Different Types of Seams in Garment Industry with Pictures:

Arrangement of fabric ends of the seam line is called seam type. According to ASTM (American Society for Testing and Materials), seam classification relates directly to the positioning of fabric sections at the junction where these sections are sewn. They are classified into following types.

- Seam class-1: Superimposed seam

- Seam class-2: Lapped seam

- Seam class-3: Bound seam

- Seam class-4: Flat seam

- Seam class-5: Decorative seam

- Seam class-6: Edge neatening

- Seam class-7 (Attaching of separate items)

- Seam class-8 (Single ply construction)

All types of seams in garment industry are described below:

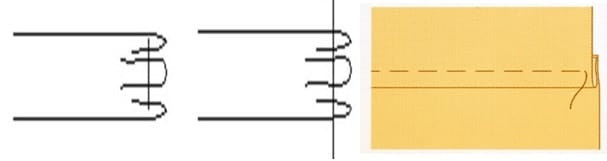

1. Seam class 1: Superimposed seam

In this kind of seam, normally two or more fabric panels are superimposed over one another and seaming was done near an edge, with one or several rows of stitches. Superimposed seam is achieved by two or more separate fabric pieces put together. This is one of the most recognized methods of seaming. Superimposed seam is sewn with a lockstitch, chain stitch, over-edge stitch or safety stitch.

Properties of superimposed seam:

- Seam is achieved by two or more separate pieces of fabric sewing together.

- Most commonly used.

- The fabric ends are in same direction.

- The most basic superimposed seam is SSa.

- It has over 50 variations.

- This class seam can be sewn a variety of machine. E.g: Lock stitch or overlock machine.

Uses: Mostly used inside seam like as shirt and pants.

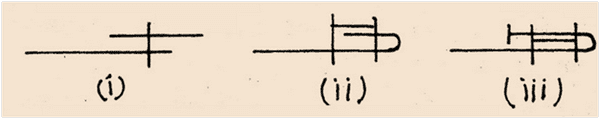

2. Seam class 2: Lapped seam

In this type of seam, two or more fabric plies are lapped with the raw edges, flat or folded and attached with one or several rows of stitches as shown in Figure 2. It is a strong seam with fabric edges, generally used to safeguard jeans fabric from fraying. Lapped seams are commonly used in joining garment parts such as yoke, gusset and other garment parts. Another class of lapped seam, French seam, comprises a two stitching process with a superseding folding operation. It is a flat, folded seam with only one row of stitching noticeable on the face side of fabric and involves a minimum of two components and can have different variations comprising a number of rows of stitching. It is commonly used for rain wear, and edge stitching front facings on jackets and dresses.

Properties of lapped seam:

- This type of seam is achieved with two or more pieces of fabric over lapping each other.

- Tow sewn ends of the fabric are in opposite direction.

- Mostly two needle chain stitch machine is used.

- Seam under this class is very strong.

Uses: Inside seam of jeans and dress shirts etc.

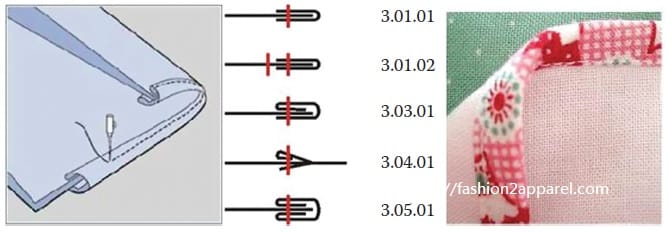

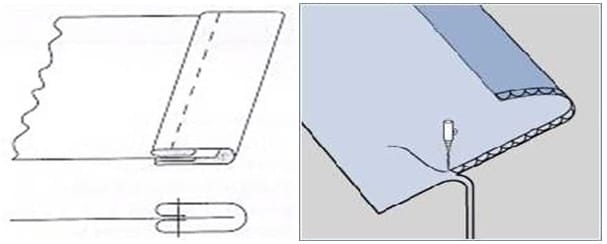

3. Seam class 3: Bound seam

Bound seam is formed by folding a binding strip over the edge of one or more plies of material and seaming the binding strip to the material with one or more rows of stitches. This bound seam is always used in edge neatening or for decorative purposes, mainly on high-quality garments (finish edges, necklines, short sleeves on T-shirts, sleeveless tank tops with binding). Bound seams deliver extra durability and strength (Figure 3) to the sewn product.

Properties of bound seam:

- A bound seam is one piece of fabric encompassing the raw edge of another piece of fabric.

- The purpose of bound seam is to finish an edge of garment.

- Some time used as decorative purpose.

- There are 18 variation of bound seam.

Uses: Neckline of a t-shirt, Yoke joint in the shirt waist band, under wire.

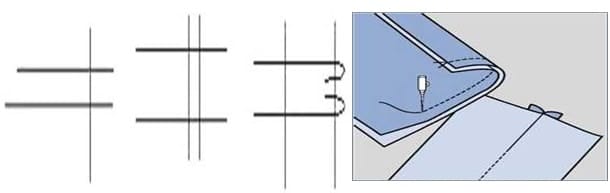

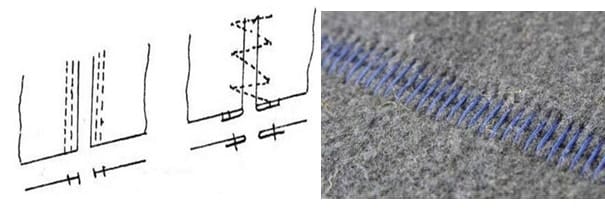

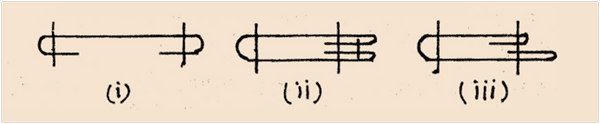

4. Seam class 4: Flat seam

Flat seam is also called a butt seam as the edges of the fabrics do not overlay one another, they will be butted together. This kind of seam is formed by sewing the abutted edges of material together in such a manner that the stitches extend across and cover or tend to cover the edges of the plies joined. The flat seam class is the smallest class with only six different types.

Properties of flat seam:

- Flat seam are constructed by having two pieces of fabric meet precisely of their edges.

- Seam thickness is comparatively less.

- Zig-zag stitch may be produced.

- Edge should be cleaned before sewing to avoid trying.

Uses: Intensively used in under garments in knit wear.

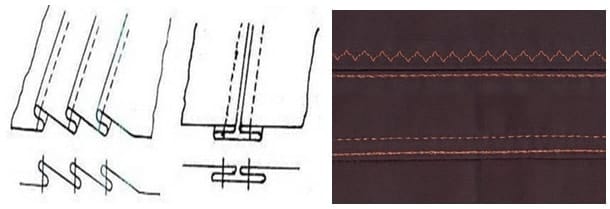

5. Seam class 5: Decorative seam

This class of seam requires a series of stitches to be embodied in a material either in a straight line, a curve or following a design, for ornamental purposes.

Properties of decorative seam:

- This type of seam is made by making one or more adjacent stitch lines in one or more layer of fabric.

- Multi needle sewing machine is used.

- Seam under this class are produced only for decorative purpose.

Uses: Used in pant or other dresses.

6. Seam class 6: Edge neatening

This class of seam requires the edge finishing to be accomplished by either sewing a series of stitches at or over the edge of a material while the edge may or may not be folded as specified, or the edge of the material is folded and stitched to the body of the material with a series of stitches.

Properties of edge neatening seam:

- Seam under this class are produced in such a way so that the fabric ends from out area cannot come out during use.

- It can be used extensively.

- It can be made by over lock machine.

Uses: Mostly used knitted garments and hemmings.

7. Seam class 7 (Attaching of separate items):

This seam class is used to attach separate components, trims, or accessories to the main garment. It is commonly used for functional and decorative purposes.

Properties of seam class 7:

- These are sometimes called applied seam because they are mainly used to a decorative material to an edge of seam such as lace-elastic.

- Similar to lapped (class-2) but the joined component is extended limited on both side from sewn line.

- This is used for joining of different parts of garments with additional or extra materials such as lace, elastic braid, elastic etc.

8. Seam class-8 (Single ply construction):

This seam class involves stitching on a single layer (ply) of fabric, rather than joining multiple fabric layers. It is primarily used for decorative stitching, edge finishing, or reinforcing edges.

Properties of seam class 8:

- Mainly one piece of fabric used.

- This class is commonly used for waist belt and loop belt.

- The edges of fabric are sewn by folding in various ways.

- Seam is made in one time completed by twin needle machine and folder.

Conclusion:

A seam is a method of joining two or more pieces of fabric together, usually using thread to form stitches. By this article we have learned about different types of seams and their uses in garment. This knowledge will help us in our professional life.

References:

- Karthik, T., Ganesan, P., & Gopalakrishnan, D. (2016). Apparel Manufacturing Technology. In CRC Press eBooks. https://doi.org/10.1201/9781315367507

- Garment Manufacturing Technology. (2015). In Elsevier eBooks. https://doi.org/10.1016/c2013-0-16494-x

- Textile-Engineering. (2024b, December 24). Different Types of Seams in Sewing and Their Properties. Textile Engineering. https://textileengineering.net/different-types-of-seams-in-sewing-and-their-properties/

- Kiron, M. I. (2022, December 2). Types of Seam Used in Garments Manufacturing. Textile Learner. https://textilelearner.net/types-of-seam-used-in-garments-manufacturing/

Editor of Fashion2Apparel. She is a fashion designer and ex-lecturer in Fashion Designing. She wants to spread fashion knowledge throughout the world.