Introduction:

The global apparel industry is one of the most important sectors of the economy in terms of investment, revenue, trade and employment generation all over the world. The global apparel manufacturing industries have undergone dramatic changes in the past four to five decades both in terms of technological changes and volume expansion. It is continuing changes time to times. It is a huge market. According to an estimate, the global apparel industry is valued at $3 trillion, and which accounts for 2 percent of the world’s Gross Domestic Product (GDP). According to Statista, The global apparel market is projected to grow in value from 1.5 trillion U.S. dollars in 2020 to about 2.25 trillion dollars by 2025. The apparel manufacturers are now adopting new techniques to increase their trade. In this article I will discuss different upcoming trends in global apparel industry and trade.

Future Trends in the Global Apparel Industry & Trade:

Technological advancements have dramatically influenced clothing and fashion in the modern age, which transformed them from ancient times into the modern world. Industrialization brought many changes into the manufacturing of clothing items.

The textile and apparel production facilities today are in a transition zone between traditional production methods and realization of highly focused design and production of value-added clothing items. A large number of smart and intelligent textiles are becoming increasingly popular and commercially successful, as they provide additional functionality in the clothing. These textiles can sense and respond to external stimuli and are able to perform special functions, which an average fabric cannot do. Smart textiles are manufactured by the application of smart materials or finishes, such as shape-memory polymers or phase-changing materials, or electronic or e-textiles.

Smart and intelligent textiles are being used in various applications such as physiological monitoring (such as heart rate, respiration rate, temperature, activity and posture), sports training data acquisition, monitoring potential external hazards or hazards involved in handling of hazardous materials and tracking the position and status of soldiers in action, innovative fashion, regain sensory perception that was previously lost by accident or birth and widely used in transportation and automotive purposes etc. To evaluate these smart textiles and clothing, new instrumental analysis techniques and new test methods should be devised. The fashion and textile designers should be adequately trained in the areas of advanced fabrics and state-of-the-art technologies used in smart textiles.

You may also like: Recent Applications of Smart Textiles

Digital printing is also a revolutionizing technical development, which allows small-quantity production and sought-after designers to create high-demand clothing without much waste. Numerous opportunities exist with digital printing, which reduces the water usage and energy consumption and minimizes textile effluents. Printing of photo-quality images directly onto fabric and reproductions of hand-painted art are the other advantages of this technique. It is widely used in advertising banner and architectural design. In future, digital printing will be widely adopted by manufacturers to precisely print customized designs in fabric as well as in garments.

The use of whole-garment or seamless technology is gaining impetus in the apparel industry due to smooth fit, comfort, invisibility and easy-care properties. Seam less technology can directly produce nearly finished product. The seamless technique helps in waste reduction, cost-saving and flexibility to incorporate certain design features. It also reduce production time by eliminating the cutting and sewing processes. It ensures higher productivity, quick response production and other advantages. The global fashion trends suggest that seamless garments are becoming popular among consumers, especially the youth. There is a potential for seamless garments to hold 50% of the industry’s sales within the next 10 years by providing educational and training facilities and adding versatile design features.

The Internet is influencing consumers’ choice of clothing as well as apparel manufacturers’ and retailers’ style of marketing approach. E-commerce and e-marketplace have revolutionized the fashion and apparel industry. Consumers can easily buy with these e-commerce site. Now apparel sales on e-commerce portals have soared beyond the expectation while surpassing the sales of all other categories. The in-store consumers can then decide whether to select the most-liked item or go for the less-liked pieces. Digital technologies also enable small, new or ethical fashion labels to gain access to markets around the globe. It is much more diversified and fragmented textile fashion industry along the entire fashion supply chain from production to distribution. In future, the Internet will influence the fashion market in ways that never happened before.

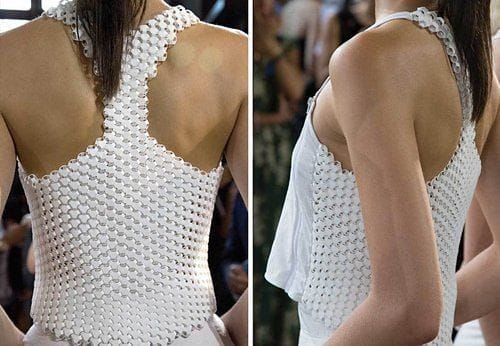

The use of 3D printing technology in clothing and fashion is rapidly growing. As the technology continues to grow, its limitations and costs will gradually diminish. The idea of mass-customized design can become a reality with the application of 3D printing, which can reduce the problem of size and fit. Who does not want to wear a one-of-a-kind, perfectly tailored piece? It can be economically used to prepare a dress to match each individual’s liking, or shoes designed for the exact shape of one’s feet. The new printing technology can open up the possibilities for personalized styles. Eric Wilson, fashion news director at InStyle magazine, said that 3-D printing could be revolutionary in the near future.

Several apparel manufacturers are moving towards a quick response and just-in-time approach, where the sold apparel items are quickly replaced by the manufacturers rather than from a large inventory kept with the retailer. The electronic data interchange and the use of barcode systems have helped in rapid communication between the manufacturer and the retailer, providing information on the consumer requirements, inventory, production progress, technical issues and delivery status. Social media such as Twitter and Facebook are helping consumers in understanding the fashion trends and getting closer to brands and the opportunity for new brands to emerge more readily.

The recent care labels used in garments are either printed or woven labels storing limited information. The electronic care labels are paving their way, which use radio frequency identification (RFID) technology for storing information electronically on a garment. However, the feasibility of this technology is a challenge due to its high cost, health risks and other technical challenges.

Although there is some automation, the apparel industries are still far behind the other sectors and rely on manual intervention. The automation of various instruments in spreading, cutting, sewing and material handling can reduce the production cost and minimize faults. Now automation is one of the major key to quality improvement and cost competitiveness. ERP (Enterprise Resource Planning) is another addition in apparel industry. ERP softwares are largely used for effective monitoring and control, accurate planning and scheduling of orders, better data predictions, quick response to query and on-line detailed information of orders. Systems like Kaizen and lean manufacturing are increasingly applied to garment manufacturing. Kaizen is a system that merges work and process improvement without increasing the cost. Kaizen involves every employee e from upper management to the jobber e and each individual is encouraged to come up with small improvement suggestions on a regular basis. Lean manufacturing focuses on achieving the shortest possible cycle time by eliminating process waste in a systematic approach and through continuous improvement. Lean manufacturing emphasises on producing the same goods utilizing fewer resources.

Design and product development will make use of 3D tools that allow for garments to be created in 3D and converted automatically to 2D for traditional manufacturing methods. Digital body models can be created by 3D body-scanning systems, which will allow the digital products to be draped over them. The simulation of these digital products on the body can be obtained from the fiber and fabric characteristics. These data can be shared digitally and monitored through the product development process without the need for the development of a physical fabric or garment sample. Various organizations will benefit from this, including equipment suppliers, logistics companies, transportation providers, advanced technology centers, educational institutions and training organizations.

Conclusion:

Apparel industry has short product life cycles, tremendous product variety, volatile and unpredictable demand, long and inflexible supply processes. Besides, consumer choice is always unpredictable and now shifting from traditional designs towards luxury high-fashion items. Apparel manufacturers should keep up with the pace of change like offering on wholesale prices. Otherwise they don’t survive in competition race.

Image courtesy:

Ebay.com

Knittingindustry.com

You may also like: Application of Latest Technology in Textile Designing

Editor of Fashion2Apparel. She is a fashion designer and ex-lecturer in Fashion Designing. She wants to spread fashion knowledge throughout the world.