What is Table Quality Inspection?

Table quality inspection is a process where finished garments are checked piece by piece on an inspection table. TQI is the mainstream inspection method. It is a crucial mid-production check performed by quality control (QC) personnel. TQI is also called “End of the line inspection system”. It is the most original inspection system the civilization has discovered in garment industry. Table quality inspection is done after finish the in-line quality inspection. This inspection aims to identify and classify defects so only flawless garments reach customers.

When production is done, each item is rigorously inspected on a table to locate any remaining defect. Garment item without defect is passed while defectives are rejected. Defectives are however, repaired if possible.

Tools and Environment Requirement for Table Quality Inspection:

The inspector who is trained must be equipped with the following tools and environment.

- A wide table (of greenish grey color) lit with day light type of tube lights; light quantity should be enough to the tune of 1,000 flux.

- A measuring tape; another measuring tape fixed on the table.

- Good quality scissors.

- Required gummed paper arrow sticker to display location of defects etc.

- Inspector must have a worksheet / P.O. sheet along with size spec.

- Inspector must have special buyer instructions, if there is any.

- For each style there should be an approved sample in close proximity to the inspector.

- If your factory has a quality manual approved by buyer, check with major & minor defects as per that manual.

- In absence of factory quality manual, should be use made of buyers manual where enlisting major & minor defects of garments.

Procedure for Table Quality Inspection in the Garment Industry:

1. Inspection Area Setup

- Ensure the table surface is clean, well-lit, and smooth.

- Provide sufficient natural or artificial lighting (ideally 1000 lux or above).

- Use a measuring tape, inspection tools, defect tags, and a checklist.

2. Garment Placement

- Lay garments flat and fully opened on the inspection table.

- Inspect both inside and outside of the garment.

- If needed, use mannequins or hang garments to inspect fit and fall.

3. Inspection Procedure

Inspectors should check the following aspects:

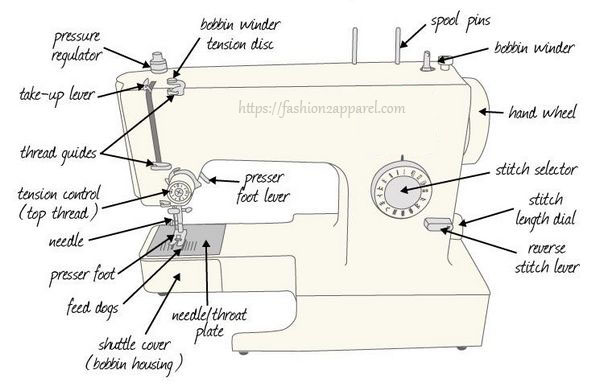

a. Stitching Quality

- Seam strength, consistency, and neatness.

- Absence of skipped stitches, broken threads, or loose ends.

- Correct SPI (Stitches Per Inch) as per spec.

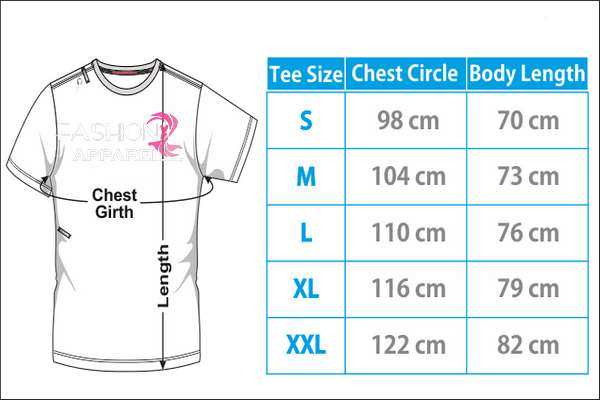

b. Measurements

- Use a measurement chart to verify major and minor points.

- Acceptable tolerance should be followed (e.g., ±0.5 cm or as per buyer standard).

c. Fabric and Trims

- Check for holes, stains, pulls, color variation, or fabric defects.

- Trims (buttons, zippers, snaps) must be correctly attached and functional.

d. Labeling and Tags

- Ensure size, brand, wash care, and price labels are correctly placed and accurate.

e. Workmanship

- Symmetry (e.g., pockets, collars).

- Proper pressing or ironing quality.

- Clean garment – no oil marks, threads, or dirt.

4. Defect Identification and Classification

Defects are usually categorized into three levels:

- Critical – Safety or legal non-compliance (e.g., broken needle in garment).

- Major – Affects function or appearance (e.g., open seam, wrong measurement).

- Minor – Does not affect functionality but affects appearance (e.g., loose thread).

- Use a defect tag or marking sticker to identify and record issues.

5. AQL Sampling Method (Optional)

If following AQL (Acceptable Quality Level):

- Use standard AQL charts (e.g., MIL-STD-105E or ISO 2859-1).

- Common levels: AQL 2.5 for major, 4.0 for minor.

- Inspect based on lot size and decide accept/reject criteria

6. Rework and Re-inspection

Segregate defective garments for rework.

- After correction, conduct a re-inspection before accepting the garment.

7. Documentation

- Maintain inspection records: quantity checked, defects found, pass/fail rate.

- Use a quality checklist or audit form.

- Report findings to quality control managers and production supervisors.

8. Inspector Guidelines

- Inspectors must be trained and familiar with quality standards.

- Avoid personal bias—follow specifications strictly.

- Use gloves if needed to avoid soiling garments.

Summary Checklist for Table Quality Inspection

| Area | Key Checks |

| Stitching | Seam strength, loose threads, stitch count |

| Measurements | Length, chest, waist, sleeve, etc. with tolerance |

| Fabric | Stains, holes, color variation, pilling |

| Trims & Accessories | Functionality and correct placement |

| Labels & Tags | Correct info, secure attachment |

| Workmanship | Neatness, symmetry, cleanliness |

| Defect Classification | Critical, Major, Minor |

| Documentation | Inspection forms, defect logs |

Conclusion

Table quality inspection in garment industry plays a vital role in ensuring that garments meet buyer expectations and international quality standards. A well-organized inspection system not only maintains product consistency but also strengthens a brand’s reliability in the global apparel market. This inspection acts as the final quality assurance barrier, preventing defective garments from leaving the factory.

By following these guidelines, factories can achieve higher quality, reduce rework, and deliver perfect garments to customers every time.

You may also like: Quality Control Plan in Apparel Industry with Template

Editor of Fashion2Apparel. She is a fashion designer and ex-lecturer in Fashion Designing. She wants to spread fashion knowledge throughout the world.