What is Garment Productivity?

When a garment factory converts its resources like labor, machines, materials, and time—into finished garments efficiently its called garment productivity. In simple terms, it measures how much output (garments) is produced with the least input (time, effort, cost).

Garment productivity is the amount of work produced (number of garments) in a given time, by a worker, team, or factory. Higher productivity means producing more garments in less time with good quality.

Why Productivity is Important in the Garment Industry?

Increasing productivity in the garment industry is essential for meeting deadlines, reducing costs, and improving overall business growth.

- Reduces production cost

- Increase sewing line efficiency

- Reduce cost per garment

- Increase output and on-time delivery

- Increases profit

- Improve quality

- Reduces waste and rework

- Uses machines and labor effectively

- Increases buyer satisfaction

Productivity Formula in Garment Industry:

Basic Productivity Formula

………………………..Output (pieces)

Productivity = ——————————–

…………………………Input (hours)

Example:

If 1 line produces 500 pieces in 10 hours:

…………………………500

Productivity = ————- = 50 pieces per hour

…………………………10

This means the line produces 50 pieces per hour.

Key Productivity Indicators in Garment Industry:

a. Line Efficiency

………………………………Total SAM Produced

Line Efficiency (%) = ————————————– ×100

………………………………Total SAM Available

b. Operator Efficiency

Tracks how efficiently a worker performs a specific operation.

c. SMV / SAM (Standard Minute Value)

Lower SMV → higher productivity.

d. DHU (Defects per Hundred Units)

Low defects = less rework = higher productivity.

Different Ways to Increase Productivity in the Garment Industry:

Here I will explain a clear, comprehensive, and practical list of the different ways to increase productivity in the garment industry. These ways are widely used in factories worldwide and cover people, processes, machines, and management.

1. Improve Operator Skills and Training

- Conduct regular skill training for sewing operators.

- Train new workers in training centers before placing them on the line.

- Provide refresher training to low-performing operators.

- Teach best handling techniques to reduce motion and fatigue.

Result: Higher operator efficiency and consistent performance.

2. Use Line Balancing

- Distribute work evenly based on SAM (Standard Allowed Minutes).

- Remove bottlenecks by adding helper or parallel stations.

- Reassign operations depending on operator capability.

Result: Smooth workflow → more pieces produced per hour.

3. Apply Better Work Methods (Method Study)

- Standardize the best method for each operation.

- To reduce unnecessary motions by using motion economy principles.

- Position tools and materials close to the operator.

- Maintain table height, seating, and lighting.

Result: Reduced cycle time and operator fatigue.

4. Use Work Aids, Attachments and Modern Machines

- Install folders, binders, edge guides, and attachments.

- Applying automation and modern technology (CAD, CAM)

- Integrated CAM

- Computer graphics

- Simulation software

- Robotics

- Use automatic thread trimming machines.

- Apply special machines like feed-off-arm, flatlock, pattern sewing machines.

Result: Faster sewing, fewer defects, lower SAM.

5. Improve Production Planning and Control

- Plan production using accurate capacity and actual efficiency.

- Before loading style, ensure that fabric, trims, and accessories are ready.

- To minimize style changes, set schedule lines.

- To reduce changeover time, load similar products together.

Result: Stable production with fewer delays.

6. Real-Time Production Monitoring

- Track hourly production targets vs. actual.

- Use digital production monitoring systems or display boards.

- Take immediate corrective actions on low output zones.

Result: Early detection of problems → higher productivity.

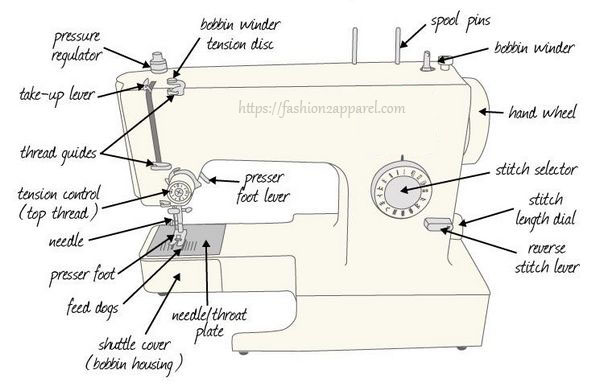

7. Maintain Machines Regularly

- Execute preventive maintenance schedules.

- Provide quick maintenance support for breakdowns.

- Keep spare bobbins, needles and critical parts ready.

Result: No downtime due to machine issues.

8. Control Work-in-Progress (WIP)

- Keep optimum WIP in the sewing line.

- Avoid too much WIP (causes clutter and delay).

- Avoid too little WIP (causes idle time).

- For smooth material movement use Kanban systems.

Result: Continuous sewing with minimal waiting time.

9. Improve Quality at Source

- Perform in-line quality checking, not only end-line.

- Train operators to self-check their work.

- To analyze defects using 5-Why or fishbone diagram.

- To prevent sewing defects ensure cutting accuracy.

Result: Less rework → more time for production.

10. Use Lean Manufacturing Tools

- 5S – Clean, organized workplace

- Kaizen – Continuous improvement

- SMED – Quick changeover

- JIT – Just-in-time material flow

- Value Stream Mapping – Identify waste

Result: Reduced waste → increased efficiency.

11. Improve Workplace Environment

- Provide comfortable seating and ergonomic layout.

- To ensure ventilation, proper lighting, and temperature control.

- Maintain clean and clutter-free floors and aisles.

Result: Reduced fatigue → better productivity.

12. Motivate Workers

- Provide performance incentives or bonus.

- Recognize high-performing employees.

- Give workers job security and respectful work culture.

- Offer growth opportunities and training.

Result: Motivated workers produce more consistently.

13. Reduce Style Changeover Time

- Before line loading prepare machines, folders, templates.

- Before production complete all approvals (PP meeting, samples).

- To reduce changeover effort, group similar designs together.

Result: More production time and less idle time.

14. Improve Material Handling

- Use trolleys, bins, and racks instead of manual handling.

- For easy tracking use color-code or barcode bundles.

- Reduce fabric defects during cutting and sewing.

Result: Faster material flow and fewer delays.

What Improves Garment Productivity the Most?

| Category | High Impact Areas |

| Operator | Training, motivation, right placement |

| Machine | Attachments, preventive maintenance |

| Process | Line balancing, method study, WIP control |

| Material | Quality material, faster movement |

| Planning | Efficient scheduling, real-time monitoring |

| Management | Lean culture, supervision, communication |

Other ways include using work aids to reduce cycle time, employing in-line quality checks to reduce rework, optimizing plant layout, and implementing incentive schemes to motivate workers. Additionally, improving communication, using motion study to correct faulty movements, and engaging employee participation in continuous improvement are valuable. Finally all combining elements like, training, technical improvements, process optimization, and motivation strategies leads to considerable productivity gains in garment manufacturing. So we can say that, to increase productivity in the garment industry is vital for staying competitive and meeting market demands.

Editor of Fashion2Apparel. She is a fashion designer and ex-lecturer in Fashion Designing. She wants to spread fashion knowledge throughout the world.