Method study:

Method study or process improvement is the process of systematic recording and critical examination of existing and proposed way of doing work, as a means of developing and applying easier and more effective methods. It is applied to increase efficiency, reduce waste, and improve overall productivity. For higher productivity in textile and garment industry method study is very important. It is one of the keys to achieving productivity improvement. Functions of method study in textile and garment industry are done by industrial engineering department.

Objectives of method study:

The major aims of method study are:

- Better design of plant equipment and buildings.

- Less fatigue or workers by avoiding unnecessary movements of manpower.

- Better working conditions and environment for workers/employees.

- To have more effective utilization of materials, machines and manpower and money.

- Better quality.

- Efficient and fast material handling equipment.

- Leads to standardization, rationalization, simplification and specialization.

- Efficient planning of the section.

- Streamlined working procedures.

- Greater job satisfaction.

- Higher earning.

- Improve layout of factory and office.

- Higher standard of safety and health.

- To improve the flow of work.

- Effective materials handling.

- Efficient process and procedure.

- To improve the proper utilization of resources.

- To get maximum output.

- To improve administration.

- Waste reduction.

- Standardization and rationalization.

Steps involved in method study:

Method study involves the following steps:

- Select the work to be studied.

- High process cost,

- Bottlenecks, tortuous route,

- Low productivity, erratic quality,

- Record the existing work method and other relevant facts:

- Activities performed

- Operators involved-how, when etc.

- Equipment and tools used,

- Materials processed or moved

- Examine the record.

- Develop optimum or alternative methods and present proposals.

- Define the method as document.

- Install this method as standard practice.

- Maintain the practice.

Activities of method study:

There are following 5 method activities as described below:

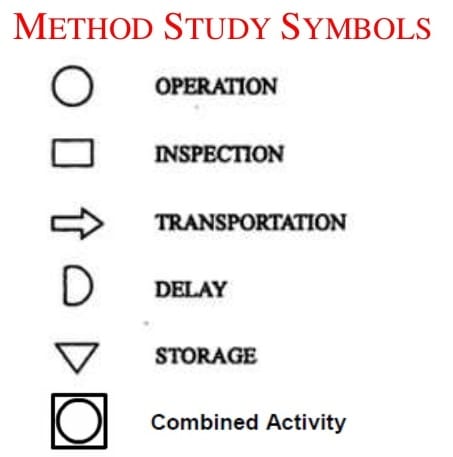

1. Operation: An operation is an action performed for advancing towards desired result. This indicates the main steps in a process, method or procedure.

2. Inspection: An inspection occurs when the product is removed for a time for production. It includes the visual observations for finish, checking the dimensions etc.

3. Storage: A storing occurs when the product is removed for a time from production. For example, materials kept in stores to be distributed to various work.

4. Delay: A delay occurs when some undesirable event prevents or hinders the next planned activity e.g. waiting for a machine to be repaired. A traffic jam. Work waiting between consecutive operations.

5. Transport: A transport occurs when there is movement from one place to another. It indicates the movement of materials from one work station to another.

Method study symbols:

In order to make a vivid presentation of facts and to enable the mind to understand them quickly and clearly, we use some symbols instead of words, for the activities of method study.

Conclusion:

Method study can lead to significant improvements in the textile and garment industry by reducing production time, increasing quality, and lowering costs. It is an ongoing process that should be integrated into the culture of the organization to ensure continuous efficiency gains.

You may also like: Production Planning and Control (PPC) in Apparel Industry

Editor of Fashion2Apparel. She is a fashion designer and ex-lecturer in Fashion Designing. She wants to spread fashion knowledge throughout the world.