Before going to operation breakdown and SAM of a men’s formal full sleeve shirt we should know about operation breakdown and SAM. Operation Breakdown means writing down all the parts and all the processes or operations in sequence wise with SMV or SAM to complete the garment and type of machines to each and every process. Style-wise operation breakdown is done by an industrial engineer in an excel chart. The operation breakdown report helps to set the line layout of every style.

SAM means Standard Allowed Minutes. It is an important factor in the garment manufacturing industry. SAM is used to measure a task or work content of a garment. In the garment factory, Industrial Engineering department measure and calculate SAM for sewing operation using standard calculation method. For the estimation of the cost of making a garment, the SAM value plays a very important role.

Operation Breakdown and SAM of Men’s Full Sleeve Formal Shirt:

| SL No. | Operations | SAM | Machine Type |

| Collar | |||

| 1 | Collar pieces joint 2 | 0.60 | SNLS |

| 2 | Collar run stitch | 0.42 | SNLS |

| 3 | Collar trim and turn | 0.25 | SNEC |

| 4 | Collar top stitch | 0.47 | SNLS |

| 5 | Band hem | 0.34 | SNLS |

| 6 | Band set | 0.65 | SNLS |

| 7 | Collar label attachment | 024 | SNLS |

| 8 | Band top | 0.45 | SNLS |

| 9 | Band and collar ready trim | 0.41 | SNEC |

| Cuff preparation | |||

| 10 | Cuff pieces joint 2 | 0.80 | SNLS |

| 11 | Cuff hem | 0.53 | SNLS |

| 12 | Cuff run stitch | 0.73 | SNLS |

| 13 | Cuff trim and tum | 0.57 | SNEC |

| 14 | Cuff top and sleeve pleat making | 0.66 | SNLS |

| Sleeve preparation | |||

| 15 | Sleeve panel attach | 030 | OL5 |

| 16 | Sleeve panel top | 0.65 | SNLS |

| 17 | Under placket attach and tacking | 0.65 | SNLS |

| 18 | Big placket attachment | 1.18 | SNLS |

| Front | |||

| 19 | Button hole placket trim and attachment | 0.56 | KANSA’ |

| 20 | Button placket sew and wash care label | 0.38 | SNLS |

| 21 | Button placket piping attach | 0.40 | SNLS |

| Back | |||

| 22 | Label attachment | 0.35 | SNLS |

| 23 | Yoke attach and top | 0.43 | SNLS |

| 24 | Dart mark and sew | 0.56 | SNLS |

| 25 | Front and back trim and pair | 030 | MANUAL |

| Assembly | |||

| 26 | Shoulder attachment and top | 0.46 | SNLS |

| 27 | Collar attach | 0.54 | SNLS |

| 28 | Collar finishing with content label | 0.85 | SNLS |

| 29 | Sleeve no set and attach | 0.85 | OL5 |

| 30 | Top stitch at armhole | 0.71 | SNLS |

| 31 | Side seam attach and sleeve trim | 0.70 | OL5 |

| 32 | Cuff no set and attaching | 028 | SNLS |

| 33 | Bottom hem | 0.67 | SNLS |

| B\S and B\H | |||

| 34 | Buttonhole front-7, cuff-2, sleeve placket 2 | 1.08 | BH |

| 35 | Button mark | 0.27 | MANUAL |

| 36 | Button front -7, spare-1, cuff 2, sleeve placket 2 | 1.17 | BTN |

| 37 | Button melting | 0.23 | IRON |

| Total | 22.10 |

References:

- Apparel Manufacturing Technology by T. Karthik, P. Ganesan, and D. Gopalakrishnan

- Practice of Garments Merchandising and Management by Engr. Md. Faruk Hosen

- Industrial Engineering in Apparel Production By V. Ramesh Babu

You may also like:

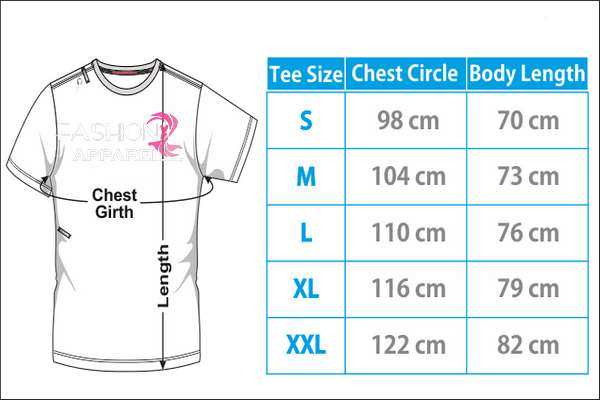

- Step by Step T-Shirt Measurement Techniques with Size Chart

- Step by Step Analysis of a Basic Shirt

- Step by Step T-Shirt Measurement Techniques with Size Chart

Editor of Fashion2Apparel. She is a fashion designer and ex-lecturer in Fashion Designing. She wants to spread fashion knowledge throughout the world.